-

Posts

485 -

Joined

-

Last visited

Everything posted by Neil ashdown

-

This information may help you to carry out your fire risk assessment https://www.london-fire.gov.uk/safety/the-workplace/pubs-bars-and-clubs/

-

I would certainly have the doors repaired, if not replaced. But for advice contact the door manufacturer. Otherwise contact the Door & Hardware Federation to find a competent maintenance & repairs company metal fire doors.

-

The requirements are that: The fire door must self-close completely and reliably to the door frame rebate stop. The maximum delay for self-closing, according to EN1154, is 25 seconds. Information at http://firecode.org.uk/Code of Practice 2009 Issue 3.pdf If a fire door is banging shut, this matter should be reported so that a competent maintenance operative can adjust or replace the self-closing device. It could be that the self-closing-device has lost fluid or that adjustment of the controls is required.

-

The requirement for smoke seals is based on the needs in terms of fire strategy at the building. For example, fire escape routes would benefit greatly from restricted spread of smoke as would sleeping areas. Having the door type (steel/timber) alone reveals nothing about any requirement for smoke seals.

-

Clearly, if you remove a lock and leave a hole in the door it should be repaired. This can be done by a competent person but the door manufacturer's fire performance certification is likely to be void due to the lack of evidence of fire resistance performance in a 'repaired state'.

-

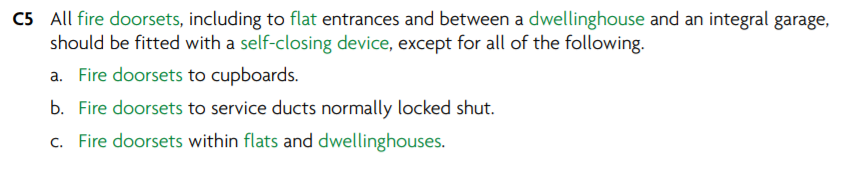

Current building regulations are here https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/937931/ADB_Vol1_Dwellings_2019_edition_inc_2020_amendments.pdf Appendix C Fire Doors, paragraph C5 deals with self-closing fire doors:

-

Consult a competent fire door inspector. They would examine the fire door assembly and then be able to advise about what can be done to improve its likely fire/smoke resistance performance. But remember, even after the works have been done a nominal door is still a nominal door.

-

The maximum gap at the threshold for a timber-based fire door should be 10mm. Therefore you may need to fit a ramped threshold plate to the floor. Where restricted smoke spread is a requirement the maximum threshold gap is 3mm. Therefore, you may need to re-lip the bottom edge of the door, fit a ramped threshold plate and a threshold smoke seal.

-

There is no reference to the use of PVC architraves in the BS 8214: 2016 Timber-based fire door assemblies - code of practice. So with reference to Flat Entrance Doors (often composite construction) I would consult the door manufacturer. Doors in communal areas are likely to be timber-based doors, therefore I would use timber-based architraves.

-

Do I need to use special paint on new fire doors?

Neil ashdown replied to a topic in Fire Doors and Accessories

Timber-based fire doors are tested for fire resistance (to BS 476 Part 22 / BSEN 1634-1) not for surface spread of flame. Therefore you may paint them. In any case water-based paints are very good, easy to use and available in a good range of colours these days. -

If you are changing the door from the house to the integral garage it would be advisable to install a self-closing fire resisting door with restricted smoke spread. If you don't want to do that, you could contact a competent consultant to see whether the works you are undertaking fall under the scope of building regulations https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/901517/Manual_to_building_regs_-_July_2020.pdf

-

How long should it take for fire door to close?

Neil ashdown replied to a topic in Fire Doors and Accessories

From what you say, it seems the self-closing devices have been incorrectly installed or possibly poorly adjusted. Contact a competent fire door installer / maintainer for assistance. -

There are UKAS accredited fire door installation schemes for companies and separately there are fire door installation training courses for individuals.

-

Advice on Door Closers

Neil ashdown replied to Lloyd Griffiths's topic in Fire Doors and Accessories

The Rutland trouble shooting guide is here https://www.rutlanduk.co.uk/data/607dd7c17c49d.pdf -

https://www.ifsa.org.uk/documents/ is the place to look for fact sheets, information and guidance about intumescent seals and smoke seals.

-

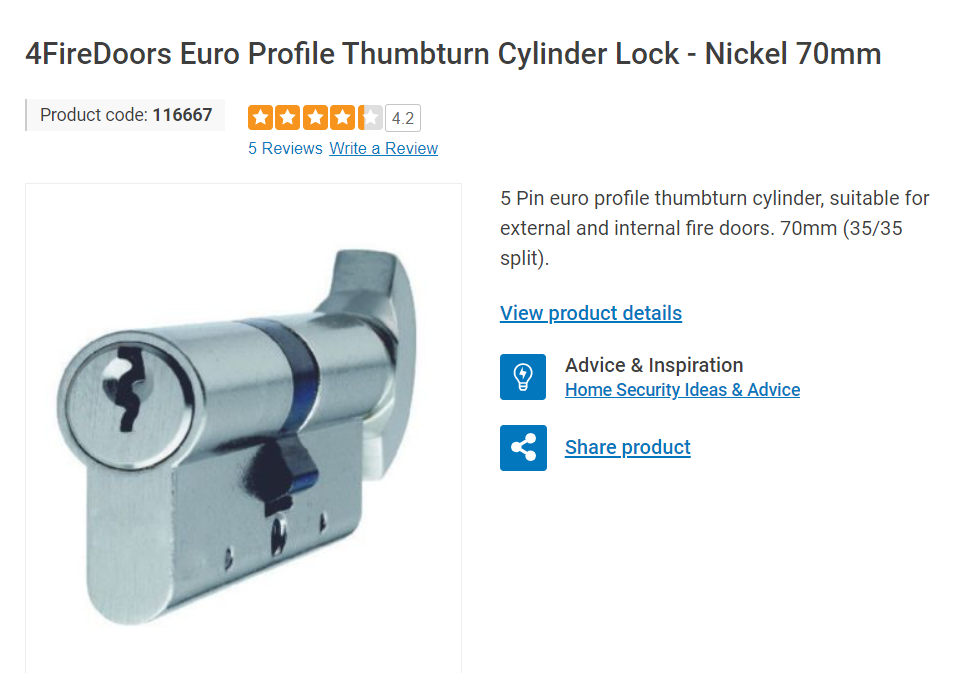

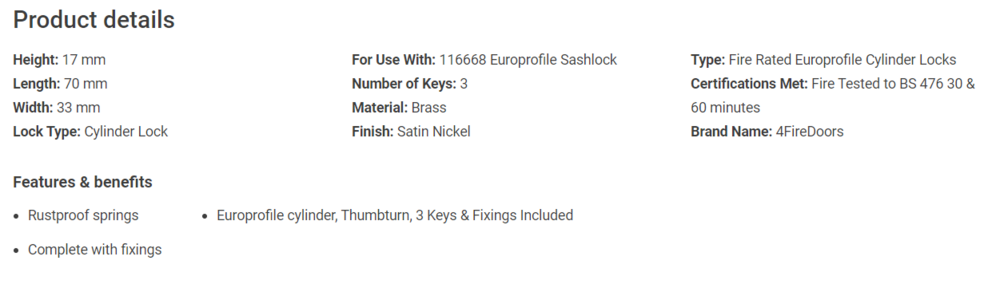

New fire door Eurocylinder replacement.

Neil ashdown replied to Bradley Hughes's topic in Fire Doors and Accessories

Be careful with like for like! Do not assume that what was originally installed is compliant. -

Applying fire retardant weatherstrip on a Fire Door

Neil ashdown replied to a topic in Fire Doors and Accessories

With the foam tape fitted, will the door self-close completely to the rebate stop of the door frame and so that the latch bolt engages fully? What happens when you try to burn the foam tape? -

Applying fire retardant weatherstrip on a Fire Door

Neil ashdown replied to a topic in Fire Doors and Accessories

Batwing type seals are available for use with fire resisting doors. This type of seal fits inside the door frame rebate so you have to ensure they can be fitted without affecting the self-closing action of the door. There are single wing versions too. -

New fire door Eurocylinder replacement.

Neil ashdown replied to Bradley Hughes's topic in Fire Doors and Accessories

When replacing the lock cylinder, to a timber-based fire resisting door, ensure that the new cylinder is suitably fire rated and that the mortice work around the cylinder is tight with no gaps. If it isn't, repair with timber/rock wool/intumescent mastic as necessary. There is no legal requirement to obtain certification particular to this this work. OTHER BRANDS ARE AVAILABLE -

-

Cold smoke brushes for door bottom gaps over 25mm

Neil ashdown replied to Martyn's topic in Fire Doors and Accessories

A threshold gap of 25mm is excessive for both fire resistance performance and smoke spread performance. Can the floor condition be remediated and/or can a threshold plate be fitted to the floor directly under the door in its closed position? -

Are specific fire door gaps a legal requirement?

Neil ashdown replied to a topic in Fire Doors and Accessories

A gap of 10mm between the edges of the door leaf and door frame is excessive, this applies at the top edge and at the vertical edges. The Standard 'BS 8214:2016 Timber based fire door assemblies - Code of practice' states that "a typical gap to achieve good fire performance is between 2mm and 4mm". -

Making good a fire door after cutting into it

Neil ashdown replied to a topic in Fire Doors and Accessories

Lipping must be of a suitable hardwood and fixed with an adhesive appropriate to the door fire rating and type of timber core/rail. Lipping should be one piece, rather than two pieces used double thickness. For FD30 minimum 6mm thick and maximum 19mm thick with maximum 2mm profiling at the corners. For FD60 minimum 6mm thick and maximum 15mm thick with maximum 2mm profiling at the corners. -

Does the door have attributes that are present on a fire resisting doors? Eg: Is it solid core, are there any markings on the top edge of the door that indicate the door is fire resisting? Are you able to satisfy yourself that the door is fire resisting?