-

Posts

483 -

Joined

-

Last visited

Everything posted by Neil ashdown

-

The issue here is not to do with the compliance of the door. The floor should be 100mm lower than the door threshold. Imagine the garage floor was flooded with petrol..............

-

space between fire door frame and opening

Neil ashdown replied to a topic in Fire Doors and Accessories

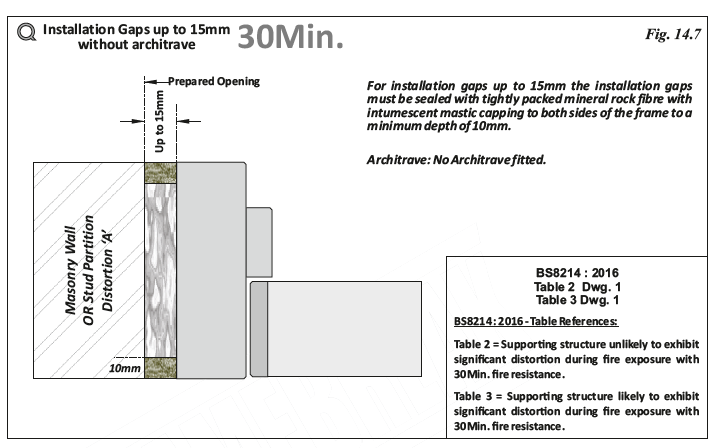

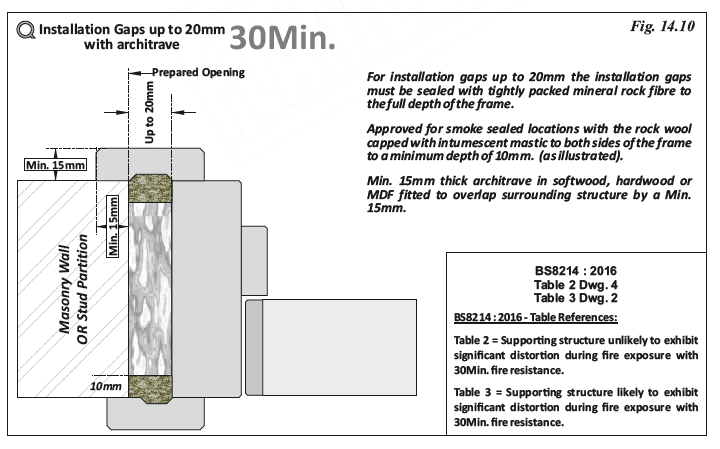

So the issue appears to be certification of the work. Normal practice would be to completely and tightly pack the gap with mineral fibre and then seal to a 10mm min depth to both sides with the Fire Acoustic Sealant. Refer to BS 8214:2016 for minimum requirements. If the architect will not allow the use of Blue 60 and the dedicated packers in place of the sealant/fibre combination, then you have two options: 1) Ask the Blue 60 manufacturers what evidence of fire performance is available for use of Blue 60 in full accordance with the fire test evidence but with an additional depth of Fire Acoustic Sealant to both sides. Note, we are saying 'in full accordance' so that the sealant is an extra-over to the fire stopping requirements. Clearly door frame material type, depth of foam and gap size is a major factor here. 2) Use mineral fibre and fire acoustic sealant in accordance with BS 8214:2016. -

Are specific fire door gaps a legal requirement?

Neil ashdown replied to a topic in Fire Doors and Accessories

When inspecting the gaps between the edges of the fire door leaf and the door frame: 1) Check the gap is between 2mm minimum and 4mm maximum, generally (consult the door leaf data sheet for certainty about the requirements). 2) Ensure that the smoke seal brush or blade (where required) is in light contact with the surface that it sweeps or compresses against, in the door fully-closed position. 3) Ensure that the door leaf does no stand proud of the door frame (and not proud of the other leaf of double doors). The door frame rebate does not provide significant protection against the spread of cold smoke, therefore smoke seals should be fitted where smoke protection is necessary. -

Obviously floor conditions can be outside the control of the fire door installer. Where the 3mm gap cannot be achieved options are fitting a threshold plate to the floor or fitting a drop-down seal to the door leaf bottom edge. Where fitting of those is not possible then the person or organization that has control of the building and responsibility for fire safety should make a risk based decision about whether the excessive gap is acceptable. If deemed not acceptable then remedial action to the floor condition will be necessary. The following is from ASDMA on BS 8214:

-

Fire Door - need a self-closer?

Neil ashdown replied to MysteryMan's topic in Fire Doors and Accessories

This type of self-closing device is designed to be easier to open. Contact the manufacturer to find out which device is best suited to your needs and that of the flat entrance door as these must be self-closing fire doors with restricted spread of smoke. -

Ditto

-

The guidance you need as follows: BS 8214: 2016 https://shop.bsigroup.com/ProductDetail/?pid=000000000030332501 IFSA https://www.ifsa.org.uk/documents Unless the brush seals are offset, there shouldn't be room for two brush seals as the gap between the edge of the door leaf and the frame should generally be 4mm max and 2mm min. Same for the gap at the meeting edges of double leaf doors. Be careful to ensure that the brush seals do not prevent the doors from self-closing completely. In the door closed position, the brush (or blade) should only lightly contact the surface that it sweeps.

-

If the seal is making a noise when the door opens, it is most likely from the brush or fin that provides restricted smoke spread protection. This type of seal needs to make light contact with the opposing surface in the door closed position so the noise is most likely due to friction. If the noise is a problem you could change the seals (all of them) for fire only seals (below) used in conjunction with the type of smoke/acoustic seal (bottom).

-

space between fire door frame and opening

Neil ashdown replied to a topic in Fire Doors and Accessories

Refer to BS 8214:2016 Timber-based fire door assemblies - Code of practice for details about how to seal the gap. -

Is it a new door? Do you have the name of the manufacturer (is there a label on the top edge of the door)?

-

Possibly repairable depending on extent of damage and of course, so long as the core of the door is not damaged.

-

Follow guidance BS 8214:2016 Timber-based fire door assemblies - Code of practice https://shop.bsigroup.com/ProductDetail/?pid=000000000030332501 with regard to specification of door assembly components.

-

Are fire doors needed in 4 storey 1920s house?

Neil ashdown replied to OliverJ's topic in Fire Doors and Accessories

Best to check with local authority building control on fire door requirements then. Protected escape route from upper floors, Approved document B (dwellings) Annex C Fire Doors. -

Are fire doors needed in 4 storey 1920s house?

Neil ashdown replied to OliverJ's topic in Fire Doors and Accessories

Does the work you are doing fall within the scope of Building Regulations? -

space between fire door frame and opening

Neil ashdown replied to a topic in Fire Doors and Accessories

Yes, timber packers should be used at all fixing points so that you can get a secure fixing. They can be full width of the door frame. Ensure the mineral wool is tightly packed to fill all gaps and leave no voids then cap the wool on both sides with a 10mm depth of intumescent mastic. -

Is an oak threshold permitted under a fire door?

Neil ashdown replied to a topic in Fire Doors and Accessories

Yes, Oak is a good timber for a fire door threshold. -

The regulations in terms of access and use of buildings is https://www.planningportal.co.uk/info/200135/approved_documents/80/part_m_-_access_to_and_use_of_buildings I would advise you to check with local authority building control as to whether your proposal is in scope of Part M requirements for dwelling houses. There are limits to how narrow a fire door leaf can be in terms of its fire resistance performance but as you haven't said how narrow the door would be, I cannot comment further.

-

Do I need to use special paint on new fire doors?

Neil ashdown replied to a topic in Fire Doors and Accessories

Assuming the fire doors are wooden ones. Strip and paint them as you would any wooden door. Do not paint over smoke seals and avoid adding metallic facings. -

This one is interesting because when timber-based doors are tested for fire resistance performance it is assumed that the door would be positioned at floor level. In fact the fire tests used in the UK are BS476 part 22 & EN1634-1 and both tests place a pressure at a certain height on the door from the furnace side, see below. However, the tests are a 'benchmark' and, as your scenario demonstrates, not always reflective of the use of the door in real life. Therefore it should be borne in mind that the fire resistance of the door in your end use may be different to its 'as tested' performance. Furthermore, the fire in a real life situation may be different in its character to the one in the BS/EN test furnace. Where you have any concerns, it would be best to discuss them with an expert in fire doors.

-

-

Government guidance can be found here https://www.gov.uk/government/publications/building-safety-advice-for-building-owners-including-fire-doors at page 29 and annexe A

-

Usually a flat entrance door that opens onto an outside area would not need to be fire resisting. However, there are some occasions where one would be necessary, such an example could be that there is a balcony / escape route above or adjacent to your door. If in doubt check with an expert.

-

To be certain you will need to check with the fire door manufacturer. The door could be composite construction or it could be solid timber? The knocker could be faced-fixed or it could be bolt through?

-

BS 8214:2016 Timber based fire door assemblies- Code of practice. Paragraph 9.5.2 deals with operating gaps "A typical gap to achieve good fire performance is between 2mm and 4mm".

-

A fire door must self-close all the way to the rebate stop. Contact an independent fire door inspector for advice. Fire door inspectors are listed at: https://fdis.co.uk/find-an-inspector-2/ and https://www.blueskycert.com/members-main/#fire