-

Posts

449 -

Joined

-

Last visited

Everything posted by Neil ashdown

-

Hospital fire door replacement - building control?

Neil ashdown replied to Mark Stanley's topic in Fire Doors and Accessories

https://www.linkedin.com/search/results/all/?keywords=fire door regulations wilkinson&origin=TYPEAHEAD_ESCAPE_HATCH&sid=Tm9 -

If the joint between the timber door frame and blockwork wall is so intimate that there's no gap, then there is no linear gap to be sealed. Where there is such a gap it should be sealed using BS 8214 guidance. Intumescent sealant should be present level with the edge of the door frame and face of the wall.

-

Rebated Fire Doors - Intumescent Seals

Neil ashdown replied to a topic in Fire Doors and Accessories

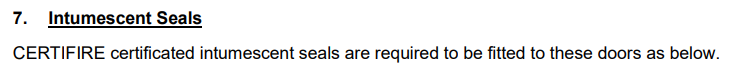

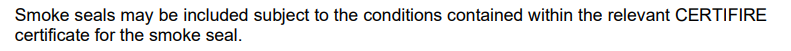

No options for smoke seals on the pull-side so check the rebates to see if the batwing will fit. When these are fitted the door must self-close completely and reliably. There may already be intumescent seals integral to the door leaf behind lipping at the vertical and top edges? Check this before making a groove in the door. If you are fitting intumescent seals though, the smoke seal could be incorporated into those. -

space between fire door frame and opening

Neil ashdown replied to a topic in Fire Doors and Accessories

I am unaware of any sealing product tested for such a large linear gap. Is the surrounding wall masonry / timber stud / metal stud? -

Rebated Fire Doors - Intumescent Seals

Neil ashdown replied to a topic in Fire Doors and Accessories

Please send image of door in the closed position from inside the server room. Looking for somewhere suitable to locate a smoke seal as unsure there's room for a compression/batwing seal within the existing rebate? -

Fixing door to frame perimeter gaps can be tricky. In the case you describe the gap is 6mm at the top corner of the closing edge and the best way to resolve would be to adjust the door frame hanging jamb by removing architraves, loosening the frame and using timber packers/wedges to adjust the jamb from the back. But if the jamb joint is morticed or let-in to the head in some way this will be time consuming and the joint may have to be widened and done again. It may be possible to pack behind the top hinge with non-combustible material but the risk is that doing so would open up a larger gap and the hinge side. Before you begin, check with your Fire Risk Assessment that the door is critical to fire safety and that this work needs to be done.

-

Upgrading certified fire doors

Neil ashdown replied to twane_tredoux's topic in Fire Doors and Accessories

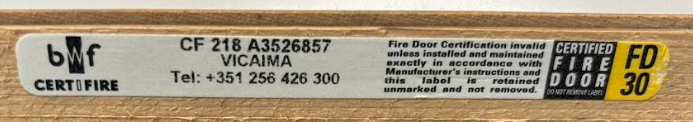

The point about a certificated fire door is that the label on the top edge of the door leaf enables you to find the certificate of approval at https://www.warringtonfire.com/certified-companies/check-a-certificate Read the certificate to find out the requirements for the smoke seals. In this way the door retains it's certification and becomes FD30(s). -

Panelled FD30s doors - minimum thickness

Neil ashdown replied to strugglinauthor's topic in Fire Doors and Accessories

You are correct, there are many modern panel effect timber-based fire doors with FD30 fire resistance performance certification. Even though when measured at the thinnest point, its much less than 44mm. I would advise you to question your fire door inspector on this matter. -

The gap should be measured at the point between the edge of the door leaf and the face of the door frame. Guidance in BS 8214: 2016 states that the gap should be between 2mm minimum and 4mm maximum for optimum fire resistance performance. For restricted spread of cold smoke the seal should fill the gap but without causing the door to catch or bind when self-closing.

-

In terms of fire resistance performance documentation from the manufacturer, generally the door leaf should not stand proud of the door frame (or other leaf in a pair) by more than 1mm. Some door certification documents state no tolerance at all. It will be necessary to assess how critical these defects could be given the safety risk at the particular location(s) within the building.

-

You try the DHF https://www.dhfonline.org.uk/ for guidance

-

3. I have also read fire risk assessments, and seen fire safety advice on company websites, that suggest an 8mm or 10mm gap at the bottom of an upgraded FD30S door, but I read this as <4mm without a threshold seal or <3mm with a drop seal. Which is the correct line? One for our resident fire door expert Neil, but if it's upgraded to achieve a notional FD30S I would expect that to include the threshold gap using a drop down seal or hardwood lipping. 'BS 8214: 2016 Timber-based Fire Door Assemblies - Code of Practice' is widely referenced with regard to the threshold gap of a fire resisting door in the closed position. In terms of a fire door, the maximum gap should be as stated by the door leaf manufacturers certification data sheet. Generally this is between 6mm and 10mm maximum. Think of this gap in terms of limiting the drawing of cold air under the door to feed the fire and limiting the amount by which door may drop should the hinges fail to support the door as the fire has an effect on the condition of the door. Doors that are required to restrict the spread of cold smoke should have a maximum gap of 3mm at the threshold. Where such a tight gap is not achievable, the gap should be sealed with a flexible strip.

-

Try this: https://www.falconpp.co.uk/media/1326/07_strebord_v91_section_7_doorframes.pdf But clearly you need to identify the door manufacturer if you are to confirm compliance.

-

Smoke passing through fire door hinges

Neil ashdown replied to Hugh Riddle's topic in Fire Doors and Accessories

Thanks. Interesting, if used in place of intumescent edge seals it would be unsuitable for some fire resisting doors that specifically state a specification for the intumescent seals required. Couldn't see any link for the product certification? -

If the door needs to a fire resisting and cold smoke restricting, self-closing door then the joiner ought to make sure their work ensures that the finished door complies with 'BS 8214: 2016 Timber-based Fire Door Assemblies - Code of Practice'.

-

Smoke passing through fire door hinges

Neil ashdown replied to Hugh Riddle's topic in Fire Doors and Accessories

You mean, in order to exceed the required Standards? There are already continuous smoke seals that reamain uninterrupted by hinges and locks because they fit to the edge of the rebate stop. https://www.lorientuk.com/products/batwing Also, ones for retrofit like this: -

Unable to comment without seeing this door. Probably, you need a replacement fire door assembly / set. Or another way of getting the bed into the flat.

-

Smoke passing through fire door hinges

Neil ashdown replied to Hugh Riddle's topic in Fire Doors and Accessories

The Standards for restricted spread of ambient temperature smoke, BS 476 part 31.1 and BS EN 1634-3, do permit leakage to a defined limit in the pressure test. Therefore smoke protection around doors should not be viewed in absolute terms. For more on smoke seals visit https://www.ifsa.org.uk The knuckle of the hinge should be positioned up to the door frame jamb and door leaf face so as to avoid 'door growth' in operation of the door. Refer to the ASDMA best practice guidance at https://asdma.com/ -

Are specific fire door gaps a legal requirement?

Neil ashdown replied to a topic in Fire Doors and Accessories

Refer to BS 8214: 2016 Timber-based Fire Door Assemblies - Code of practice. This guidance documents states that gaps should be 2mm min to 4mm max for optimum fire resistance performance. You don't say whether these doors require smoke protection, in which case this type of seal may provide a solution. Unsealed contact of the door leaf with the rebate stop of the door frame is insufficient in terms of optimum fire performance and restricted smoke spread. -

Yes it can but you need to repair the door and frame, back to its factory state, before you install. Make sure the door leaf is solid core, not Tubeboard or panelled.

-

fire doors with concealed intumescent strip

Neil ashdown replied to a topic in Fire Doors and Accessories

The door hardware needs to be compatible with the fire door leaf but not always necessarilly fire rated. Check the available evidence of fire performance for the door leaf for the hardware specification. -

If you require an FD30 door there's no problem using a 54mm thick (potentialy FD60) door leaf. If single leaf door, the seals should usually be central. Can't say more without seeing the door in the flesh.

-

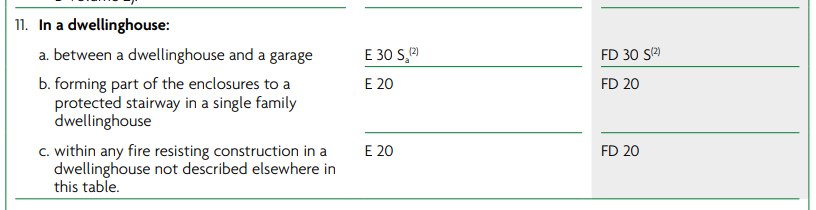

Door threshold for door between house and garage

Neil ashdown replied to a topic in Fire Doors and Accessories

Surely the floor of the garage is at a level considerably lower than the bottom edge of the door and I would expect the door frame to already have a flush cill? If you can identify the fire door to it's manufacturer or it's certification you will be able to find out the requirements for the threshold and Section 12.3 of BS 8214: 2016 Timber-based Fire Door assemblies - Code of Practice provides guidance about smoke sealing at the threshold. -

Door from garage to conservatory

Neil ashdown replied to Peter M's topic in Fire Doors and Accessories

See Approved Document B for the current building regulations at https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/1124733/Approved_Document_B__fire_safety__volume_1_-_Dwellings__2019_edition_incorporating_2020_and_2022_amendments.pdf Table C1 Page 139 It seems the question would be 'does your conservatory form part of the house?' -

Making good a fire door after cutting into it

Neil ashdown replied to a topic in Fire Doors and Accessories

That depends what the certification data sheet or other fire performance related documentation requires. Is any available?