-

Posts

447 -

Joined

-

Last visited

Posts posted by Neil ashdown

-

-

This type of self-closing device is installed into mortice holes in the top edge of the door leaf and door frame head. The arm is connected at the device and at the door frame head. The top edge of the door is partially scalloped to accommodate the arm.

It is important to understand that only specific timber-based fire doors are suitable for this type of self closer, they must have evidence of fire resistance performance when fitted with the particular self-closing device.

Furthermore, certain additional works will likely be required such as thicker hardwood lipping at the door leaf top edge, increased thickness of the door frame head and the use of intumescent gaskets to line the mortice work. Where the door must restrict the spread of cold smoke it will be necessary to ensure that the smoke seal continues past the device. The device should always come with installation instructions and documentary evidence of fire performance.

-

I expect you mean an intumescent air transfer grille? These do not restrict the spread of cold-smoke, so only where the fire risk assessment allows.

-

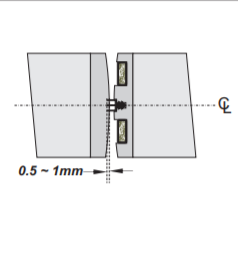

For this type of door, the maximum threshold gap should be 3mm because building regulations require the fire resisting doors in common areas of blocks of flats to provide restricted spread of cold smoke. Refer to BS 8214:2016 Timber-based fire door assemblies - Code of practice, section 12.3.

The use of a suitable threshold plate will certainly make it much easier to achieve this gap and Building Regulations Part M compliant ones are available. However, if a hazard assessment has ruled them out it will be necessary to fix a hardwood lipping to the door leaf bottom edge and/or fit a drop-down or static threshold seal. Survey each door to see which remedy is most suitable for the particular door.

Whether or not a timber-based fire door leaf may be fitted with a hardwood lipping will depend on the construction type of that particular fire door and possibly whether the original installer over-trimmed the door leaf when they fitted it.

When resolving edge and threshold gap issues, it is sometimes necessary to remove the complete door and frame assembly and re-install to the correct tolerances. The gap between the door frame and the surrounding wall substrate should be within the scope of the requirements set out in the document BS 8214:2016 Timber-based fire door assemblies - Code of practice, section 9.

-

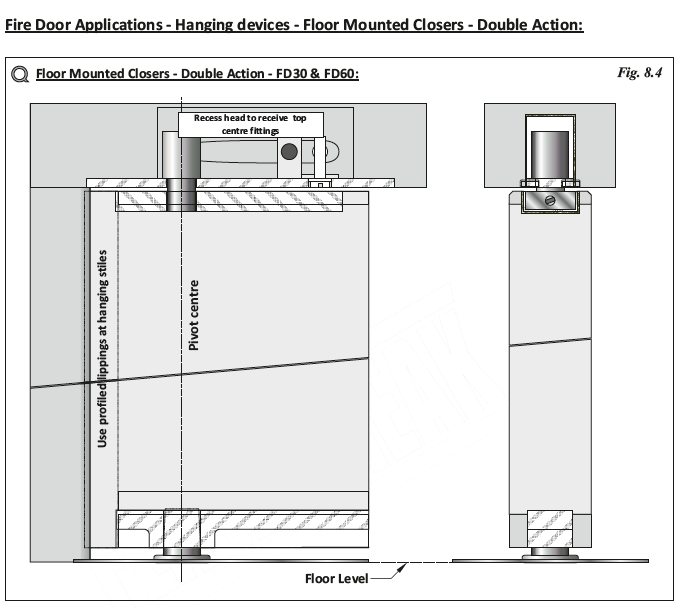

For a double-swing-action timber-based fire door it will be necessary to use pivots instead of hinges. It will likely be necessary to use a floor=spring instead of an overhead self-closing device.

Not all timber-based fire doors will be suitable for this application, so consult a specialist fire door supplier/manufacturer. And follow the installation instructions for that particular door leaf.

-

BS 8214: 2016 Timber fire door assemblies: Code of practice states that, for doors that must restrict the spread of cold smoke, the threshold gap should be no greater than 3mm at any point.

A 12mm gap is likely to be too large even for a fire door without the restricted spread of cold smoke requirement. You will likely need to install a threshold plate to the floor in remediation.

-

From what you say, it seems that somebody has made an aperture in the door leaf at some point? Are there any identification marks on the top edge or hanging edge of the door leaf? Whereabouts in the door leaf has the aperture been cut and how large is the aperture? Is it a flush door or a panel door and how thick is the door leaf at the point where the aperture has been cut?

Photographs can be useful in cases such as these.

-

That's right, in order to find out what type and size of hinges as well as whether intumescent gaskets are required you would need to check the door leaf/door-set manufacturer's installation data sheet. I note that its a new installation, so the manufacturer's installation data sheet will be available.

-

Some composite fire door-sets will have a manufacturer's label at the door frame head underside. This provides traceability to the manufacturer so that you can contact them for information about the fire resistance rating of the door. If the fire door has third-party certification there should be a label or coloured plug fitted to one edge (usually top or hanging) of the door leaf providing details about the fire resistance rating for the door and traceability to the manufacturer.

If the client has no certification, what other documentation relating to the doors do they have? Such documents may be used to trace the product to the manufacturer. https://www.thefis.org/mhclg-advice-note-17/

-

Clearly, if you are fabricating a fire door blank to produce a fire door then you must do this work within the scope of the evidence of fire resistance performance that relates to that particular door blank. You must pass the evidence of fire resistance performance, including the installation requirements therein, to your customer.

-

Is the fire door inspector referring to building regulations or the British Standard? Both have been updated since 2003. Ask the fire door inspector to provide details about the non-compliance issues, why they are non-compliant and to what standard or reference point.

-

Try these glazing experts for advice https://www.houzz.co.uk/professionals/doors/hulin-associates-pfvwgb-pf~1351733639

-

The door must reliably self-close to the rebate stop of the door frame. The smoke seals around the perimeter of the door should seal the gap between the door leaf and frame. Similarly at the threshold, the seal should seal the gap or if the threshold gap is no greater than 3mm then a seal is not required.

These are requirements of BS 8214:2016 https://shop.bsigroup.com/ProductDetail/?pid=000000000030332501

-

When you say fill an old mortice lock, I am assuming either the lock is not required and you need to fill the mortice hole or that the mortice hole is too large for the lock and you need to fill the residual void or gap.

I am also assuming the door is timber-based FD30 and that you cannot refer to the manufacturer for advice.

If that is correct, then the hole should be tightly plugged with solid timber and any very small residual gaps filled with intumescent mastic. The edge of the door should be re-lipped with hardwood (density 640 kg per m3 or more) minimum 6mm thickness. The adhesive used for those repairs should be urea formaldehyde based.

-

Fire resisting doors are tested to either BS476 part 22 or BSEN 1634-1. One side of the door is subject to fire and the criteria for a successful test is that the door does not allow fire to spread to the non-fire side.

In the test door hardware such as handles and locks are fitted to the door so that it can be demonstrated that the hardware does not cause the door to fail. That does not mean that the handle/lock should be operational at the end of the test, only that fitting of the handle/lock must not cause the door to fail the fire performance test.

Code locks and smart locks must be proven to not cause the fire door to fail to meet the requirements of the fire performance test.

You may find this useful

-

On a single leaf door, you should not fit intumescent seals to the door leaf edge where one is already fitted to the door frame.

Image below seal shows options.

-

Yes, so long as you carry out the work within the scope of the technical data sheet for the fire door leaf. Contact the door leaf manufacturer for advice but if you cannot find out who made the door leaf consult a competent person before starting work.

-

Depends what is permitted under the requirements of the door leaf manufacturers certification data sheet. Is this a new fire door leaf? Or have you fabricated the door from a fire door blank? Or are we talking about an existing fire door but with no evidence of fire performance?

-

First deal with the glazed panel issue. Check they are fire rated and if not, assuming fire resistance is a requirement, replace with an FR glazing system. Use the link Tom has provided for some helpful guidance.

The client should be aware that double-action fire doors present compliance problems in terms of fire resistance and smoke spread as compared to single-action doors. If fire safety the the priority the client would be well advised to stick with single-action doors.

If they wish to press ahead with replacement fire doors it will be necessary to survey the existing door frame for suitability. If the replacement doors are double-action the door frame will need to be suitable to house the concealed pivot and self-closing system and the door leaves will need to be 54mm thick with suitable lipping/blocking to accept the pivot/self-closing system. The GEZE TS 500 NV system (Certifire CF259) might suit your clients needs.

-

There's this one too https://www.lorientuk.com/products/batwing

-

https://www.lorientuk.com/products/single-batwing Data sheet available, follow the link and contact the manufacturer as necessary.

-

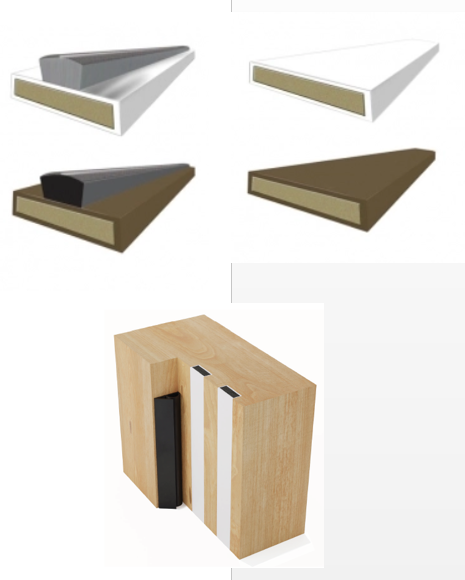

The lipping should be hardwood at least 640 kg/m3, at least 6mm retained thickness (after planing-in) and must not be in addition to existing lipping. Adhesive should be urea formaldehyde. Use a carpenter that has sufficient knowledge about timber-based fire door installation, maintenance and repairs.

-

There are two options here, the problem being that many timber-based fire doors have an integral top rail that should not be over-trimmed:

1) Always replace existing door frames rather than fitting a new door leaf only. This is most often necessary to achieve compliant installation.

2) If you must retain the existing door frame, then the door leaf must be custom made to suit the door frame.

Furthermore, if you must retain the existing door frame ensure the following:

A) The framing material is in good condition and of suitable dimensions and density.

B) The existing hardware (hinges/locks) positions are suitable for the new door leaf. Any redundant cut-outs to the door frame must be competently repaired.

C) The size and sealing of gap between the door frame and the surrounding wall meets the requirements of BS 8214.

-

Seals should be fitted to the main leaf only so as not to be interrupted by flush bolts at the top and bottom edge of the secondary leaf. Where there is no bolt the seals may be fitted to the meeting edges of both leaves but offset, not opposing.

-

Can the door leaves be trimmed to suit the frames?

Fire door gaps

in Fire Doors and Accessories

Posted

Fire fire doors, with regard to restricted smoke spread the excerpt above is from building regulations in England & Wales Approved Document B, Table C1. Looking at 2a it can be seen that smoke leakage is allowed but not exceeding the stated rate, from the head and jambs only. There is no mention of the threshold gap.

Section 12.3 at BS 8214:2016 provide specific guidance about the gap at the threshold and the following information from www.ifsa.org.uk may be useful:

"Because it is perceived to be difficult to achieve a seal at the threshold, the gap at the bottom of the door is exempted from the leakage criterion in Approved Document B. As the gap at the bottom of the door is straight through and is invariably wider than elsewhere in the assembly, then if the smoke is truly mixed and at an even pressure and temperature, a greater proportion of the smoke is likely to be egressing from this gap than any of the others. The pragmatic decision to ignore the leakage from the bottom assumes that there will be some stratification of the gases and, therefore, less polluted air will be present nearer to the floor level. This cannot be guaranteed and so leakage through the threshold gap would lead to rapid smoke logging of the protected space. There are, therefore, real benefits to be achieved if the threshold is sealed to satisfy similar levels of performance. This is something that has been recognised in BS 9999 and BS 9991, where it is recommended that for an adequately smoke sealed door the threshold is sealed with a drop down seal, or one that makes continuous contact with the floor, or where this not practicable that the gap at the bottom of the door is controlled to 3mm".