-

Posts

446 -

Joined

-

Last visited

Posts posted by Neil ashdown

-

-

The guidance document BS 8214: 2016 'Timber-based fire door assemblies-Code of practice' deals with threshold gaps for restricted cold smoke spread requirements in section 12.3.

So its clear that, when installing fire doors to that standard, the door bottom edge to floor covering/threshold plate gap should not exceed that specified by the fire door leaf manufacturer, this is commonly 6mm to 10mm.

Where the door is required to restrict spread of cold smoke the threshold gap should not exceed 3mm. Where a 3mm gap cannot be achieved (due to floor condition) a suitable threshold plate or ramp should be fitted to the floor and/or a threshold seal to the door leaf as necessary.

In terms of responsibility, its impossible to answer your question because details of the agreement between you and your client are unknown. Eg. Who carried out the pre-works survey?

In my view, the fire door installer should inform the client about threshold gap requirements and recommend suitable solutions (as described above) where gaps are excessive. Hope this helps.

-

Falcon Panel Products are the importer of Flamebreak and have a very good technical dept. https://www.falconpp.co.uk/contact/

-

Here is a link https://www.warringtoncertification.com/certificates/CF257/5606/CF257 Pyroguard.pdf to a Certifire certificate of approval and data sheet for Pyroguard.

Check with the joiner that this is the product they will be using. The data sheet provides you with details about the fire resistance performance of the product, how it may be used, its limitations and how it should be installed.

If he is not a Competent Person, why would you consider engaging his services?

And don't forget to check whether you are required to notify Local Building Control.

-

This topic also applies to your question:

-

There is currently no legal requirement for a fire door installer to possess a dedicated qualification or certification. However, building operators must comply with the requirements of the Regulatory Reform (Fire Safety) Order 2005. Articles 17 and 18 deal with maintenance and competence.

-

Any repairs to fire doors must be done in such a way as to improve and not detract from the likely fire resistance performance of the door.

Clearly repairing a damaged door is likely to improve its fire performance but take care to use the correct materials. Hardwood for lippings should be between 6mm and 18mm thick for FD30 and 8mm and 15mm for FD60. It would be wise to avoid the use of Beech (certainly for FD60) and density of the timber should be 640 kg per cubic metre or more. Use urea formaldehyde based adhesives.

Clearly, when repairing a nominal door there is no certification data sheet or fire resistance report to refer to, but by identifying the core material: Timber, Chipboard or Tubecore, you can find technical information in the public domain and therefore ensure the repairs meet the requirements of doors similar to the ones you are repairing.

Two things to remember though: 1) This work should be done by Competent Persons as referenced in Article 18 of the 2005 Fire Safety Order, 2) A Nominal fire door has no evidence of fire performance and therefore risk of failure to provide fire performance is greater that that of an evidenced or certificated fire door. Ensure such risks are dealt with in the Fire Risk Assessment for your building. It would likely be prudent to replace the fire door instead of repair it in some locations where risk to harm is more likely!

With regard to opposing fire seals, this can sometimes be an issue. How much of an issue is likely to depend on whether the door is latched or unlatched, whether it is single leaf or double leaf and whether it is single acting or double acting.

Finally, look at guidance documents available for upgrading timber based fire doors (TRADA is a good source), and for seals visit ifsa.org.uk , get a copy of Code of practice Hardware for Fire & Escape Doors and the BS 8214 : 2016 Timber-based Fire door assemblies - Code of practice.

-

A fire resistant partition will always be a complete system comprising the boards, studwork, fixings and infill etc. all installed as fire test evidence requires https://www.british-gypsum.com/literature/white-book for example

There are also fire rated products for use where the services pass through the partition https://www.rockwool.co.uk/product-overview/fire-stopping-products/ for example.

Other brands are available.

-

-

Maximum threshold gap for FD60(s) is 3mm. Refer to BS 8214:2016 Timber based fire door assemblies Code of practice

-

The handles do not need to be fire rated. However, the installation works for the handles must not compromise the fire and smoke resistance performance of the fire doors.

-

For metal fire door-sets you would have to contact the manufacturer for gap requirements.

-

Contact the door leaf manufacturer to find out the adhesive requirements for that particular door type. Intumescent seals are best positioned in the door frame but it is acceptable to fit them to the door leaf edges as an alternative.

An inspector cannot 'over-rule' product certification.

-

The top edge of the door is potentially most vulnerable in a fire situation. Without seeing the door and the 'gap' you mention it is impossible to say whether an effective repair might be possible.

-

Both FD30s and FD60s would require smoke seals to restrict the spread of smoke at the door leaf to door frame gap at the top edge and all vertical edges. The door threshold will also need to be compliant.

-

You may be right? If you post a picture of the seal somebody may be able to identify it?

You say the fire doors are less than two years old, so you should be able to check this with the installer, supplier and manufacturer??

-

If the gap is more than the widely accepted '4mm rule' then there is greater risk that the door will fail to meet its intended fire resistance performance. Make sure your fire risk assessment deals effectively with this non-compliance issue.

-

It is permissible to fit hardwood lippings to timber-fire resisting doors. Make sure the lipping is the correct type of hardwood, to the correct minimum and maximum dimensions and use the correct adhesive to suit the type of door core.

Obviously, don't add a new lipping on to an existing lipping!

-

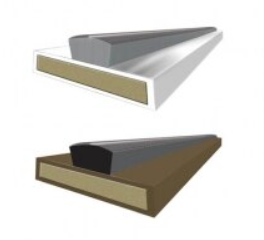

These plain seals can go in the door or frame, they are intumescent fire seals.

These combined intumescent fire and smoke seals can go the door or frame.

Batwing type smoke seals can be fitted in the corner of the rebate, against the stop. They are not intumescent so use them with the intumescent fire only seals.

Smoke seals are also available to fit to the stop on the push side of the door, these are not intumescent so use them with the intumescent fire only seals.

-

Use a small hand held bottle router with a trimmer bit. Failing that sand off the surplus. Make sure you use the correct adhesive for lipping the door leaf.

-

It depends whether the door must also provide restricted smoke spread as well as fire resistance.

Where there is a restricted smoke spread requirement the maximum gap is 3mm (refer to BS 8214:2016).

For timber based fire doors and where there the is no such smoke requirement the maximum gap is generally between 6mm and 10mm, depending on the evidence of performance for the particular fire door. So it is very unlikely that a gap of more than 10mm will be compliant for any timber-based fire door.

Where the 3mm gap requirement for restricted smoke spread cannot be met due to floor conditions, a threshold smoke seal / threshold plate will be required to close the gap accordingly.

-

Composite fire doors are currently available for sale.

With regard to the Government tests there's more information at https://www.gov.uk/government/publications/fire-door-testing-grp-composite-test-results

-

Yes. The architrave should not be relied upon to provide fire resistance.

-

The contractor doing the remedial work to the fire doors does not have to possess any particular certification or qualifications BUT they must be COMPETENT. Refer to Article 17 and article 18 of the fire safety order.

http://www.legislation.gov.uk/uksi/2005/1541/article/17/made

http://www.legislation.gov.uk/uksi/2005/1541/article/18/made

-

Opening resistance of unlatched fire doors.

in Fire Doors and Accessories

Posted

The standard for door self-closing devices is BS EN 1154. For a fire door the device should be minimum power-size 3 and have controls for adjustment of closing speed and damping action. Section three of the document 'Hardware for Fire & Escape Doors - Code of Practice' at http://www.firecode.org.uk/Code_of_Practice_hardware_for_fire_and_escape_doors.pdf#:~:text=Code of Practice%3A Hardware for Fire and Escape,on fire-resisting doors and doorsets%2C and escape doors. provides detailed information.