-

Posts

439 -

Joined

-

Last visited

Posts posted by Neil ashdown

-

-

It is acceptable to router a groove in the top and vertical edges of the timber-based fire door leaf or leaves. The groove should be central to the leaf thickness except at the meeting edges of double door leaves where two offset seals may be a requirement. Do not fit a seal to a slave leaf that has flush bolts at its meeting edge, fit the seal to the main leaf instead.

The groove must be only just large enough to accept the seals as a tight fit. Take care to make sure the groove is only just deep enough to suit the seal thickness as the seal must be flush with the door leaf edge.

If you can find a BWF Certifire label (see below) on the door leaf you can refer to the CF certification data sheet for details about the type, configuration and size of seals required. If the groove will damage the BWF Certifire label, carefully remove it and reposition it alongside the groove.

-

The standard for timber-based fire doors is BS 8214 and section 9.5.2 says: "Failure of fire resisting doors under test is very often due to burn-through at the operating gap between the door leaf edge and the door frame. A typical gap to achieve good fire performance is between 2mm and 4mm". So the question is: can you justify acceptance of gaps of slightly more than 4mm?

1) Are you happy to make a note in your Fire Risk Assessment that the fire doors have been inspected and that some of the gaps are non-compliant, but that you find this acceptable in certain circumstances?

2) Has the C.O.W. checked that the cold smoke seals are effective? An excessive gap will affect the smoke restriction performance of some types of cold smoke seal.

3) Could such non-compliancies have any impact on the safety of persons at the building in a fire?

Post-Grenfell some flat entrance doors were tested by the Government and found to fail at 15 minutes rather than the required 30 minutes. This non-compliance was considered sufficient for the government to require that some fire door manufacturers cease production until further investigations were completed.

-

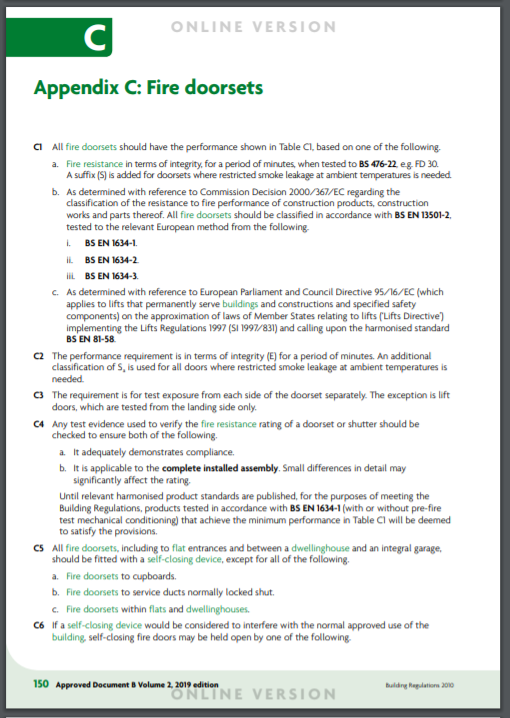

The requirements to comply with Building Regulations can be found at https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/832633/Approved_Document_B__fire_safety__volume_2_-_2019_edition.pdf

Appendix C deals with fire doors and states that they must meet the required fire resistance requirement when tested to BS 476 - 22 or EN 1634 - 1. Therefore, as I understand the requirements, your bespoke design will need to be supported by documentary evidence.

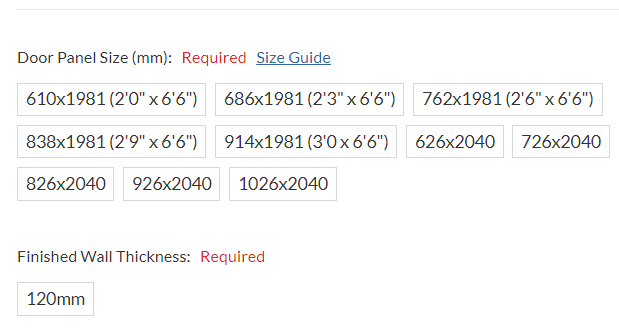

Fire door manufacturers will be able to provide you with maximum leaf dimensions and suitable configurations but I am not aware of a single leaf door that meets your specification.

https://www.eclisse.co.uk/classic-double-fire-rated-pocket-door-system/

-

Clearly, keyless egress is a useful life protection measure in an emergency scenario. If you need to open the door in an emergency and the key is not to hand that could increase the risk to life safety.

However, my understanding is that in England & Wales, the Fire Safety Order 2005 does not apply inside your own private home. Check at http://www.legislation.gov.uk/uksi/2005/1541/contents/made and you could check Building Regs at https://www.gov.uk/government/publications/fire-safety-approved-document-b

Or you could retain the keyless egress but use a security chain to help restrict the door being opened, when it shouldn't.

-

I would advise you to consult a local building regulations expert on this matter. In the meantime, this may be useful? https://www2.gov.scot/resource/buildingstandards/2016Domestic/chunks/ch03.html But check for recent updates!

-

I would advise you to consult a local building regulations expert on this matter. In the meantime, this may be useful? https://www2.gov.scot/resource/buildingstandards/2016Domestic/chunks/ch03.html

This may be useful? http://www.doorfingerprotector.co.uk/

-

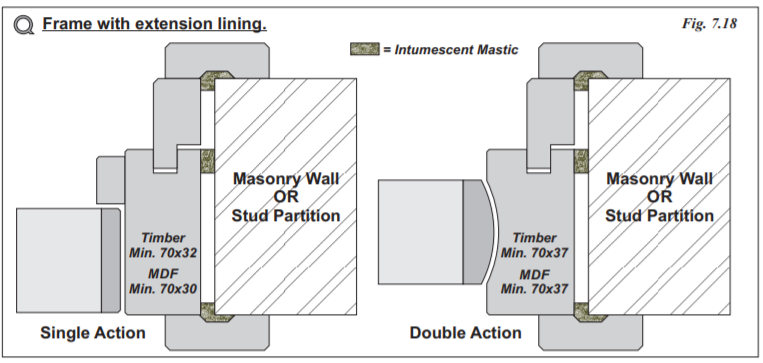

Detail below illustrates accepted method for door frame / lining extension to suit wider walls. Generally, FD30 door frames may be softwood minimum density 450kg per cu mtr and for FD60 hardwood 640kg per cu mtr (at 15% moisture content). Generally door fame thickness minimum 32mm plus the rebate stop by 70mm minimum width.

Hope this helps.

-

Think this a new product? Saw one like it on Twitter the other day.

The correct answer to your question is that the product manufacturer should be consulted to check that a fire performance test, (to BS 476-22 or EN 1634-1) has been carried out and that the product did not adversely affect the door in that test. Alternatively, where you have the door leaf manufacturers details you can check with them to see if they permit the fitting of this device without any conflict with the door's fire performance.

Assuming you have none of the above, then proceed with caution and consider the following:

1) Could fitting this product to the door leaf increase the risk of accidental foot injury?

2) Could fitting this product compromise the fire performance of doors that have a metal face protection plate (by holding the plate against the door rather than allowing the plate to fall away in a fire)?

From a fire safety angle my own view on this product, bearing in mind that I haven't yet seen one, is that due to the fact that the product would most likely be positioned at the face of the door very near to the bottom edge with short screw fixings it is unlikely to have a great affect on fire resistance performance. There would be a question about the durability of the product in terms of how well the screws perform in providing a secure fixing in the longer term. Clearly, bolt-through fixings would be more durable but are more likely to affect fire performance, particularly where a metal plate has been fitted to the face of the door.

-

Thank you Bob, glad to be of use. I will do my best to take your questions one by one..............

Architrave

Architrave is fitted to the door frame surround, but my reading of the door certificate and test report, and other documentation seems not to give definitive credance to the protection provided by the architrave, almost suggesting that the test results should be viewed as if Architrave is not fitted, yet other writings suggest a 19mm thick architrave does provide some protection.

Could I draw from this that, as archtrave comes in many differing styles (Ovolo, ogee, Torus etc etc) the thickness of these at the point of nailing (and gap covering) is often less than 19mm, usually nailed with thin panel pins, and a softwood, so its not always viewed as offering reliable protection ... and hence the need for mastic in any gaps behind.

A: Fire doors are fire resistance tested without architraves fitted. Generally, for the reasons you state, the architrave should not be relied upon as a contributor to fire performance. Clearly, though, where architraves are securely fitted as described in BS 8214 they would likely enhance the fire resistance performance of the door.

Building Control

How much should you rely on Building Control to advise on fire protection in a buildings fabric, if you seek approval from them for a specific solution to a problem (ie pentrations through a 60 minuite ceiling, and glass in a 60 minute wall), and they approve your proposal, and it is installed correctly, can you be confident they will advise correctly, or should you seek more specialised advice. I am using a large national private Building Control company.A: The Building Control officer may not be a specialist in passive fire safety, their job is to see that the works meet the requirements of the Building Regulations. With that in mind, I am of the opinion that it is better and safer to consult a specialist to advise on a particular fire resistance issue.

Fire Protection Details.

Is it normal for an architect to advise on Fire matters with Fire Protection Details on BC plans, or should one look to Building Control to advise, do Building Control look over plans prior to works and over rule/make additional direction on Fire matters to that of the architect.A: Sorry, I can't answer that one as it's beyond the level of my experience in Building Control matters.

-

The Fire Risk Assessment for the building should state whether a fire door is required for that room.

What is the risk of fire starting in that room? What would be the risk to others were a fire to start in that room? What measures can be taken to deal with and mitigate the effects of a fire starting in that room?

-

'BS 8214:2016 Timber-based fire door assemblies - Code of practice' places no restrictions on the type of paint or lacquer in terms of the fire resistance performance of the door.

The issue with paint or lacquer is that build up of layers of oil or solvent based paint or lacquer may increase the rate of the spread of flames across a surface in a fire. Surface spread of flame is very different to the fire resistance of a door so when painting doors, walls and ceilings take account of the use of the building in terms of surface fire spread considerations.

Surface spread of flame test:

-

13 hours ago, AnthonyB said:

Damaging labels is why it's preferred to put the seals in the frame and not the door, solves your problem - fire door frames often have the channels pre-cut.

Good advice! Although it seems Ben is installing the door leaf to an existing frame, hence the head problem.

Best practice is always to install a complete new fire door assembly or fire door-set because using an existing door frame means you will carry forward any door frame defects such as:

> Has the gap between the frame and the wall been sealed correctly?

> Do the hinge positions and lock positions suit the installation requirements for the new fire door leaf?

> Does the frame sectional size and material suit the installation requirements new fire door leaf?

> Can the door leaf and door frame be aligned correctly?

> Is the frame adequately fixed to the wall?

Consult BS 8214:2016 Timber-based fire doors Code of practice for information.

-

HI Ben,

Answers based on my knowledge and experience, below:

Q: We have to router the head of the door to fit intumescent strip but this ruins the certificate sticker on the door.

So we take pics of it before as evidence? A: YES in accordance with the certification data sheet for the fire door leaf and keep a record of the work done and the door's certification.

Q: And can we cut head of door to fit out of level frame head too? A: Only if the certification data sheet for the fire door leaf permits.

PS. You can find the certification data sheet from the certification number on the 'certificate sticker'.

Hope this helps.

-

Q: Is there any requirement to have handles on a 30 min fire door ? NO

Q: I have Yale type night latches with no little button to hold the latch (do they need to be fire rated and stamped ?) YES, if fitted to a fire door the lock should be fire rated

Q: and seperate mortice euro locks with no handles but with thumb turn cylinder inside. YES, if fitted to a fire door the lock should be fire rated

Q: eg can I have the Yale type latch and two mortice locks with thumb turns ? DEPENDS, check the door manufacturer's data sheet

Q: or is that too many locks on one door ? COULD BE, check the door manufacturer's data sheet

These links may be useful http://www.firecode.org.uk/Code_of_Practice_hardware_for_fire_and_escape_doors.pdf and https://shop.bsigroup.com/ProductDetail/?pid=000000000030332501

My answers are based on whether it could be possible that the lock might affect the fire performance of the fire door. An incorrectly fitted lock, or one that is not fire rated, could potentially affect the fire resistance performance of a door. This is why fire doors should be installed in accordance with the door manufacturer's requirements.

Clearly unless you have checked that the locks fitted are compliant to the installation data sheet for the fire door, there will be some 'unknowns' about the door's fire resistance performance. The more 'unknowns' you have about the doors' fire resistance performance then the greater the potential risk of failure in a fire, so take account of this 'risk' in your fire risk assessment.

-

There are various types of smoke seal including types that are separate from the intumescent strip. https://www.lorientuk.com/products/architectural-seals/perimeter-seals

So the 4mm maximum gap should not be an issue at all and make sure your fire door upgrading contractor has the necessary competence !!

-

You would need to seek advice from a competent fire door upgrading contractor or fire door inspector. There's a variety of fire door upgrading products on the market but not all doors are suitable for upgrading.

-

Hi Jake,

Yours is a common issue at existing buildings of all types. The issue with fire resisting doors is that the installed fire door should replicate the one tested/assessed to the fire performance tests BS 476 part 22 and/or BS EN 1634-1. The guidance document BS 8214:2016 Timber-based fire doors Code of practice is the standard for installation, inspection, maintenance and repairs for timber-based fire doors.

Unfortunately, adding thin strips (1mm to 5mm thick say) of timber would not be a suitable repair.

To rectify excessive door leaf to door frame gaps, the preferred method is to either: pack behind hinge blades with suitable low pressure intumescent gasket material whilst taking care that the hanging edge gap remains at 4mm maximum OR to loosen the door frame and use timber folding-wedges to adjust the door to frame gap. Whilst the architraves are removed there exists an opportunity to check that the door frame to wall gap has been sealed correctly. As a last resort it may be necessary to remove the door lipping and fit thicker (at least 6mm) hardwood lippings. These are jobs for Competent Persons.

Ensure your maintenance team follow best practice advice https://shop.bsigroup.com/ProductDetail/?pid=000000000030332501 & https://www.asdma.com/knowledge-centre/

Hope this is helpful, Neil.

-

Hi Steve M,

In my experience, having completed the FDIS Diploma, FDIS Transition module (to become CertFDI) and the one day BRE/DHF Fire Door Inspection course, the FDIS package is by far the more comprehensive fire door inspection education package available in the UK.

On the other side of the coin, the BRE course can be completed in one day whereas the FDIS package would likely take a number of weeks. You could also look at the Doorcheck one day course at Ilford, I have completed that one too.

I must declare that I held the post of FDIS manager for three years, but that shouldn't prevent me from taking an objective view!

Hope this brief summary helps. Feel free to contact me with any specific questions.

Neil.

-

Hi Bob,

The gap between the door frame and surrounding wall construction would typically be between 5mm and 20mm. BS 8214 is a very useful document in ensuring compliance of this work. Timber packers / folding wedges are preferable to plastic packers but plastic may be used so long as they are cut back by at least 10mm on both sides of the frame and covered over with a bead of intumescent mastic at least 10mm thick.

Fire foams tested to BS 476 part 22 or EN1634-1 may be used but only within the scope of the fire test evidence, this may mean using dedicated packers as part of the tested fire sealing system.

The image below illustrates the door frame to wall gap tightly packed with mineral wool but note that a 10mm bead of intumescent mastic is required to BOTH SIDES!

Hope this helps, Neil.

-

Hi again Peter,

Just to add: The doors as you described them would not be classified as Nominal Fire Doors.

A Nominal (or Notional) Fire Door is one where there exists no evidence of fire resistance performance but that in the opinion of the Competent Person would meet the required fire resistance performance.

What you describe, is a door that has been upgraded to a fire door using products that have evidence of fire performance when fitted or applied to that particular type of door.

-

Timber is an excellent material for fire doors because from empirical evidence we can easily predict its likely behaviour in a fire. When subject to fire the timber will burn and a char will form on the burnt surfaces, eventually the burn-rate will cause the door to shrink in size and bow/twist towards the fire...........and then it will fail to provide fire separation.

The burn rate of the timber will depend on its density. Therefore the less dense the timber and the thinner the door, the earlier the door will fail and for that reason fire doors are generally at least 44mm in thickness and made from solid timber-based material.

When upgrading timber doors to fire resistant doors , it is important to consider the fire performance test evidence for the products used to facilitate the upgrading works. All such products have limitations to their use/performance and the door that is to be upgraded must be comparable in its construction (density, thickness construction type) to the door that was successfully fire tested. Look carefully at the evidence of fire performance for the proposed upgrading products and check they have been successfully fire tested when used with a door of similar type, construction, density and thickness to yours.

-

Scottish building regulation technical handbook (domestic) can be found here https://www2.gov.scot/Resource/0052/00521748.pdf

2.1 Compartmentation - on page 63 and 2.9.2 Escape within dwellings - on page 86, would appear most relevant. In accordance with Tom, my advice is to consult a local building regulations professional to assist in correct interpretation and that reference is made to the current requirements.

An overview of Scottish requirements in terms of fire safety in buildings may be found here https://sp-bpr-en-prod-cdnep.azureedge.net/published/2017/11/3/Scottish-Building-Standards-and-Fire-Safety--A-Brief-Overview/SB 17-73.pdf

-

Generally speaking, intumescent gaskets are not usually necessary for FD30 timber based fire doors but are necessary for FD60. However, different door leaves may have different requirements so where the door leaf can be identified to its installation instructions or data sheet then the information about requirements for hinges should be followed in its entirety.

The intumescent gasket, where fitted, is required behind both hinge blades.

-

Where possible, loosen the frame fixings to the wall and pack behind the door frame with timber folding wedges. Re-fix the door frame when the correct gaps have been achieved. Clearly, it will be necessary to make good the fire-stopping between the frame and wall.

When carrying out these works refer to 'BS 8214:2016 Timber-based fire door assemblies Code of practice' and (where available) the product data sheet/installation instructions for the fire door leaf.

Mr

in Fire Doors and Accessories

Posted

Use this search facility to find a fire door inspector https://fdis.co.uk/find-an-inspector-2/ Enter your post code to find local fire door inspectors.