-

Posts

446 -

Joined

-

Last visited

Posts posted by Neil ashdown

-

-

A door of that age may not have identification to a certification scheme. However, guidance permits 'Notional Fire Doors' in certain circumstances. Refer to the document 'Fire Safety in Purpose Built Blocks of Flats' at https://www.gov.uk/government/publications/fire-safety-in-purpose-built-blocks-of-flats

If in doubt about the suitability of the doors to meet FD30(s) requirements, you could engage a competent person to undertake a fire door inspection and issue an inspection report.

-

In order to be compliant with 'BS 8214: 2016 Timber-based fire door assemblies - Code of practice' in terms of restricted smoke spread a suitable threshold seal is required. If this is not possible the maximum gap should be 3mm.

Would a Part M compliant ramped threshold plate fitted in conjunction with a static threshold seal be acceptable in respect of the 'older vulnerable people'? See below:

-

Are the doors meant to be fire resisting doors? Is the final exit a dedicated escape door? These are unusual for a house, is it an HMO?

-

No. If the doors are timber-based and in good condition, you may be able to adjust the door frame (re-position the jambs) to reduce the gap(s). This will involve pretty much removing the existing door frame and reinstalling to fit the door leaves as well as making sure the linear gap between frame and wall is compliant post-works.

If in doubt, consult a competent person.

-

No problem with the timber fire door frames having 25mm rebates but perimeter intumescent fire seals and smoke seals are essential. I think you won't find that listed as a legal requirement but in terms of fire door compliance with the Regulatory Reform (Fire Safety) Order 2005 it would be very difficult, I believe, to justify the absence of these seals. Especially where sleeping accommodation is present and to protect means of escape.

Check out the Intumescent Fire Seals Association at ifsa.org.uk

-

The panels could be third party certificated as part of a fire door-set, in which case the complete door-set would carry a certification scheme label or plug. But they don't have to be, working in scope of the evidence of fire resistance performance for the door is sufficient to achieve compliance to BS 8214.

-

Side panels and over panels for fire resisting doors can be of solid timber or glass, both are subject to a fire performance test or fire resistance assessment report.

Solid timber panels would be made from the same core or blank as the door leaf - refer to the technical data for the particular door in question.

With regard to glazed panels - the glass manufacturer will possess data to demonstrate fire resistance performance when used with a particular timber-based door type / door frame panel / glass retention system. This guidance document may be useful https://www.ggf.org.uk/publications/fire-resistant-glazing-publications/guide-best-practice-specification-use-fire-resistant-glazed-systems/

Currently in the UK, internal fire doors may not be CE marked.

-

Are smoke seals necessary given the use of the building and the location of the doors?

Did any of the doors ever have smoke seals fitted?

If you can identify the manufacturer of the doors to confirm their fire rating they may be able to recommend a suitable seal, otherwise you could contact a door seals specialist for advice.

If smoke seals are necessary then, in my experience bat-wing seals fitted into the corner of the door frame rebate and at the corner of the astragal for double leaf doors are the most suitable, provided that there's room in the rebate to accommodate the thickness of the seal. As they are self adhesive, the surface will need to be very clean for them to adhere.

-

From what you say, Delboy, I am struggling to see how the fire door assessor has reached the conclusion that new doors are required. That's not to say that some upgrading wouldn't be recommended.

-

If you would like some fire door installation training you could 'google' "Fire door training". There are a few providers that have websites.

Or if you don't require training, you could look at UKAS accredited third party certification schemes for fire door installation.

-

So have they given a reason why they must be replaced?

-

4 hours ago, delboy said:

We are now being told that the Windsor style cross corridor doors MUST be replaced with new doors.

No reason is being given other than ` old ones do not comply`

There has been no such change. I would push them about exactly why these doors do not 'comply' and what it is they do not 'comply' with.

-

If you are fitting a new fire door then the door leaf manufacturers installation instructions or fire performance certification will state door frame and rebate stop requirements.

If you are working on old fire doors and without the possibility of checking with the manufacturer work on 12mm minimum thickness so long as intumescent strips are fitted. If intumescent strips are not fitted, my advice is to fit them.

FD20/FD30 = softwood or hardwood FD60 = hardwood only You can use pins or screws, but stops must be securely fixed.

-

If the store rooms are small, used as cupboards and there is no self-closing device fitted to the door it must be kept locked. Fit a Fire Door Keep Locked sign to the outside face of the door.

If the door is self-closing it does not need to be kept locked but must be kept shut. Fit Fire Door Keep Shut signs to both faces of the door.

In Scotland the building regs state a maximum size for the cupboard for such scenarios.

Guidance can be found in the document 'Code of practice: Hardware for Fire & Escape doors' at http://www.firecode.org.uk/

-

For metal fire doors there is no standard for this so it must be as required by the particular door manufacturer. However, generally I would work on 10mm max for a fire door and where smoke protection is required seal the gap to the floor with a threshold seal/plate combination. If it is impractical to fit a threshold seal then the gap should be 3mm max.

-

The floor mounted threshold plate should be at least as wide as the thickness of the door leaf.

The threshold smoke seal should seal the gap along the entire length with a light even contact but not exhibit too much force and cause difficulty with the door self-closing action. If it is impractical to fit a threshold seal, the gap should not exceed 3mm at any point. For fire doors that are not required to restrict the spread of smoke the threshold gap should generally be 10mm maximum or whatever is required by the particular door manufacturer.

-

This can be difficult to resolve, you may need to invest in a high-power-size cam action self-closing device with an adjustable latching action. Speak to a competent architectural ironmonger or a self-closer manufacturer for advice.

When adjusting the closing speed its best to set the speed to quite slow so that the air can escape more easily (reducing the vacuum) as the door closes.

-

The certification for the new fire door leaf will state the specification requirements for the timber door frame.

-

I would contact local building control on this one.

-

If you take the risk, one consequence could be a problem if you decide to sell the house. Another consequence could be a problem if there's a fire.

-

As you say, an auto-drop seal will not solve the 'soup-bowl' issue. And a static door bottom seal will either not fully seal the gap or cause the door to bind on the step.

So there's a choice; fire door compliance or fire door non-compliance (BS8214). In my experience, non-compliance seems to be the popular choice.

-

Judging this in isolation. This defect appears to have been caused by the fixing screw being inserted without sufficient piloting. Fortunately, the split in the hardwood lipping appears to be slight.

If the this is a new door installation, then the defect should not be accepted. The door should be repaired by re-lipping in accordance with its certification (if its a fire door).

If the door is existing and say been there since the building was built, then ask yourself how long has it been like this? Let's say the answer is two years. Has the defect got worse in those two years? YES or NO From the picture, it looks like the answer could be no, so you could justify filling with acrylic wood filler and monitoring the defect.

-

Ha Ha......This is fire doors we are talking about. Thanks.

-

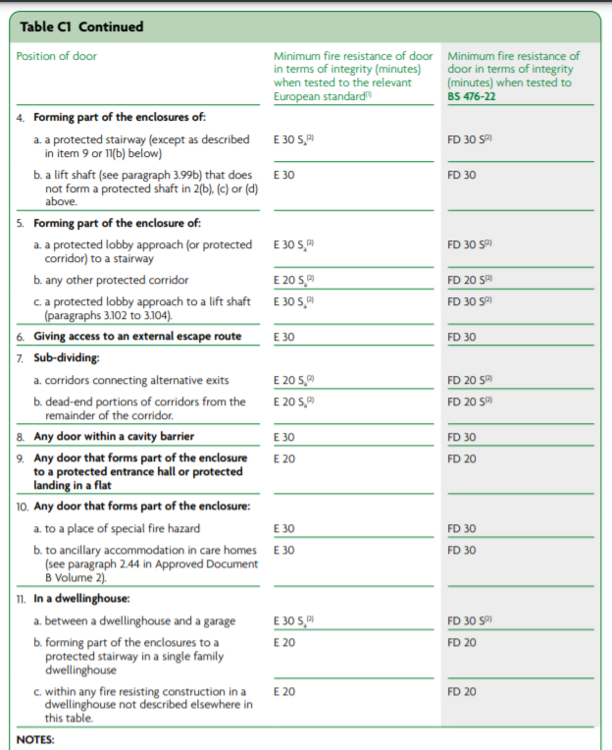

Table C1 at page 138 of Approved Document B of the Building Regulations deals with requirements for fire resisting doors in dwelling houses with loft conversion

For information about hardware / ironmongery for fire doors, consult the guidance document 'Code of Practice -Hardware for Fire & Escape Doors' at http://www.firecode.org.uk/

Blade versus brush

in Fire Doors and Accessories

Posted

In my experience the brush is certainly more durable but the blade offers less friction so as to allow the door to self-close more reliably. Have a look at this https://www.ifsa.org.uk/documents/ you might find it useful at some point.