-

Posts

427 -

Joined

-

Last visited

Posts posted by Neil ashdown

-

-

Whilst there is currently no legal requirement for fire door installers and maintainers to possess a dedicated qualification, competence is necessary. The Regulatory Reform (Fire Safety) Order 2005 requires those that provide fire safety related services to be ‘Competent Persons’. Approved Document 7 of the Building Regulations covers workmanship and materials. Many clients such as housing associations, healthcare organisations and education providers now require that those that install or maintain fire doors have a qualification or certification as proof of competence to perform those works.

Subsequent to the Hackitt Report there are industry led working groups looking at what competence should look like and you may find the recent report ‘Setting the Bar’ interesting at https://cic.org.uk/setting-the-bar-annexes.php

-

There is also Regulation 10 applicable to multi occupancy residential blocks above 11 metres in storey height https://www.gov.uk/government/publications/fire-safety-england-regulations-2022/fact-sheet-fire-doors-regulation-10

-

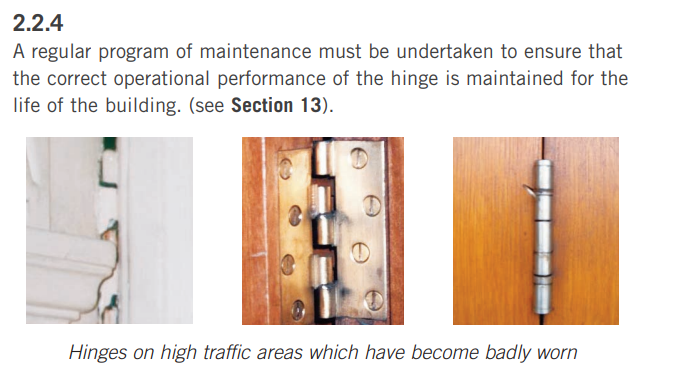

Assuming the doors are timber-based, BS 8214: 2016 Timber-based Fire Door Assemblies - Code of practice section 13 recognises that doors "do deteriorate" and says that "It is important, therefore, for inspection, maintenance and repair of any damage be undertaken on a regular basis if the fire resistance is to be maintained".

-

40mm / 50mm gaps are too large to be filled. Assuming the door assembly is timber, refer to section 9 of BS 8214: 2016.

I would reduce the gap to 20mm max using tightly fitted solid timber lining screw fixed to the back of the door frame. The lining must be continuous, full width and of similar material to the existing door frame. Alternatively, you could install a new door frame.

-

In terms of cold smoke, probably not. Do the doors have cold smoke seals and intumescent fire seals fitted?

-

This depends on the type, size and position of the concealed self-closing device.

From what you say about the advice given by the certified carpenter it seems you may be referring to an uncontrolled Perko type chain-closer with a small footprint?

If its a controlled device (with a much larger footprint) it could be that the certified carpenter is advocating that the door can be returned to a suitable condition if the concealed self-closer is removed and the void completely and tightly filled, to a high standard of workmanship, with the same materials as the door is made from. In this case, the repair would most likely be outside the scope of the door manufacturer's certification and therefore such certification would be void.

-

Remove the surplus oil. Then monitor the condition of the hinges and where there is evidence of wear / separation at the bearings replace the complete set. http://firecode.org.uk/Code_of_Practice_hardware_for_fire_and_escape_doors.pdf

-

-

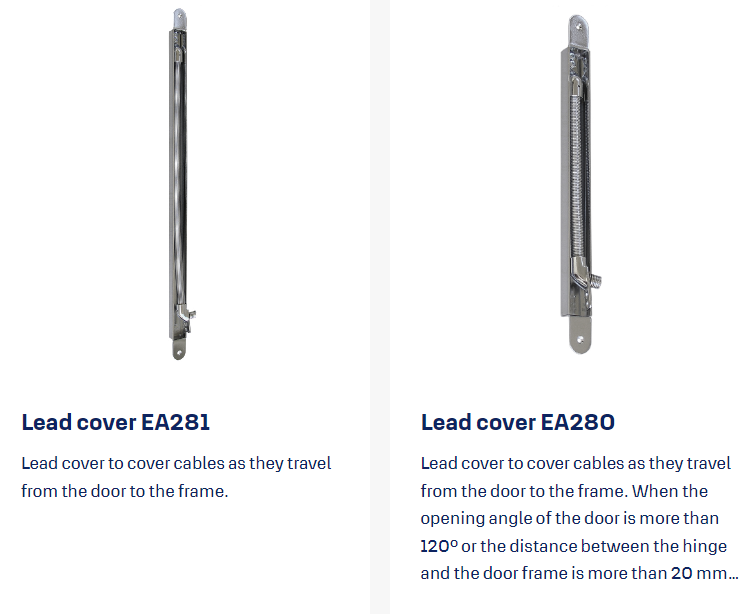

It's a lead cover https://www.abloy.com/gb/en/products/wired-locking/electric-locks/accessories/cable-ea210 and commonly used where a cable is required for an electric lock/strike.

In terms of whether its allowed on a fire door, as fire doors must have evidence of fire resistance performance including the components fitted to them, you would need to consult the fire door manufacturer.

-

The door to be upgraded would require inspection by a competent person before recommending upgrading products and materials.

-

In the UK, various materials are used for the core of a fire resisting door. The most common is timber and/or chipboard but some composite fire doors have a core of foam within a timber frame. Metal fire doors are also available.

British Standards for fire doors are for fire resistance performance tests rather that construction materials. Refer to BS 476 part 22 : 1987 and BSEN 1634-1 : 2014

-

Any door in a shared wall between a garage and dwelling house should be a self-closing FD30(s) fire resisting door.

-

In terms of compliance with the British Standard, that would not be a suitable solution. If it's a new fire door leaf refer to the data sheet for details and if its an existing fire door fitting a threshold plate to the floor may be the easiest way to resolve the problem.

-

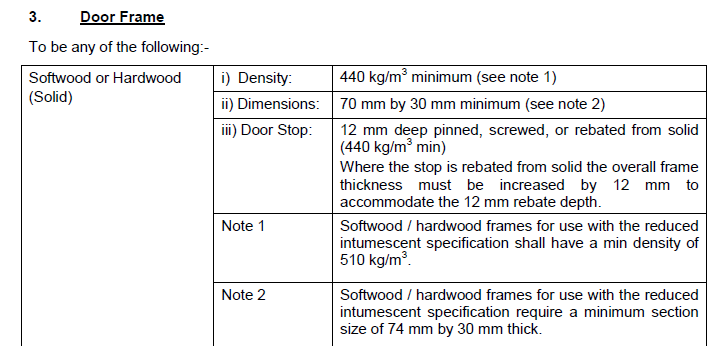

In the case of timber-based fire doors, the certificate of approval and data sheet (or equivalent documentary evidence of fire resistance performance) for that particular fire door leaf will set out the requirements for the door frame. Usually softwood with minimum sectional dimensions of 70mm wide x 30mm thick plus the thickness of the rebate stop.

Eg:

-

Escape provision would be dependent on Building Regulations where they apply. Where they don't apply, the Fire Risk Assessment should deal with the issue. In terms of cutting the top of a fire door at an angle, this is very likely to affect its fire resistance performance. Always check with the door manufacturer before cutting!

-

-

You are correct there are issues surrounding lipping min & max thicknesses, type of adhesive and density of timber. A good maintenance training course will deal with these issues.

Also, if the door is in scope of a 'third party product certification scheme' such work may cause the certification to be void. Mind, it already is when the gaps are too large!

Best practice would be to remove the door leaf and door frame, adjust the door frame to suit the door leaf and re-install the door assembly compliant in all dimensional requirements including all gaps and alignment.

-

-

The doors should be latched and the slave leaf bolted. The installation instructions for the door leaves will provide the information about whether the doors are suitable for a double leaf configuration and about the latch you need.

-

The utility room becomes part of the house therefore fire and smoke compartmentation including a self-closing fire door with restricted smoke spread would be required between the utility room and the garage.

-

The relevant British Standard, BS 8214, states "A typical gap to achieve good fire performance is between 2mm and 4mm". Excessive door leaf to door frame gaps could cause failure of the door to meet the required fire resistance performance.

-

-

Engage or consult a competent fire door inspector https://afdi.org.uk/category/find-a-fire-door-inspector/

-

The max gap depends on the sealing method employed. Contact the product distributor to find out the max gap/min depth and suitable substrates for the Blue60 system https://blue-60.co.uk/

Thumb turn lock in riser

in Fire Doors and Accessories

Posted

I would advise your employer to carry out a risk assessment for this issue. If it is felt that there exists a risk of a person being trapped inside then the lock should be changed to provide for keyless egress.