Mike North

Power Member-

Posts

329 -

Joined

-

Last visited

Everything posted by Mike North

-

Current regulations

-

I think that the question is are the 30 minute doors complaint in the location, if they are not then that also calls into question the serving shutters

-

Unfortunately, I have 6 buildings built to the same design, 2 (the first and last) have FD30S the others have FD60S in the same positions, so the strategy is of no help. The designers have ceased trading, so they won’t help, and the buildings were constructed by Carillion so not help there. The FRA is not concerned about strategy of the building as long as there is one in place, and who would spot the doors are a different rating without reviewing them side by side. Neil, I cannot use a place of special fire hazard (kitchen is not in the definition) , or ancillary because of the size approx. 30%

-

I am looking at a large dining facility with a large kitchen included. The kitchen is separated from the eating and service area by block-work walls. All frying has its own Ansul suppression facilities. At the moment there is a difference of opinion as to the rating if the fire doors. 1. The kitchen is ancillary and therefore should be separated from the dining area as a compartment and have 60-minute doors, complies with ADB. 2. BS 9999, Table 29, allows for separation of a dining area from the associated from a kitchen by 30-minute wall with 30 min doors. The question is which one is right and why

-

You should have a fire strategy for the building, however if the premisses are simple there is no need for an approved one. A competent assessor should be able to surmise were the fire walls are in a simple building

-

-

If it is a fire exit door, then no. As for a gate, that all depends on whether you can still get to a place of safety which may or may not be off the premises.

-

Front door to flat in Victorian conversion - fire door?

Mike North replied to a topic in Fire Prevention

Communal spaces (which would include doors opening on to the space) are covered under the RRO and a fire risk assessment should be in place, as the lease holder you are probably responsible. Any insurance company will ask to see the latest fire risk assessment before they payout following a fire -

In the event of a fire the first port of call for the insurers would be the fire risk assessment, if that mentioned the door is not compliant then there will no no payout. Then will be the fire authority looking at the assessment, which may lead to a prosecution under the RRO as you have ignored the recommendation of the FRA. As for time limits once a FRA has been completed, the actions should be completed in a reasonable time frame, given they are quoting 12 weeks delivery I’d say 16 weeks would be reasonable. As for lack of funding for a valid reason, that would be down to the man in the curly wig

-

Neil If they become unavailable, I have a major problem since I have approximately 10,000 of them

-

-

Porch in ground floor flat converted Victorian house

Mike North replied to a topic in Fire Doors and Accessories

Provided that there are no doors above, I agree -

There is no legal requirement to have the CF number on the top of the door, it merely proves that the door blank manufacturer was a member of the scheme at the time of manufacture. It does however make it easier to prove the door is a fire door, the invoice should provide this information. The brush seal is there for cold smoke and not fire

-

Can a Fire Door Inspector sign off the work?

Mike North replied to Fiona's topic in Fire Doors and Accessories

You don’t need to get the doors signed off, unless the hotel wants 1/3 party accreditation, then yes he can as long as is a member of the scheme -

If you are using the same pocket, you may need an intumescent gasket, but as long as all parts carry CE marks you should be OK

-

For an additional cost of £320 per door I would change the doors. If they are the original doors, you have had your moneys worth out of them.

-

Since you have a shared landing, yes

-

-

3 story extension - 1930’s / alarms Vs doors

Mike North replied to a topic in Fire Doors and Accessories

There must be a protected route from the loft to the building exit, unfortunately been open plan this is no longer an option, therefore to compensate you need an L1 fire alarm. -

Smoke seals are designed to contact the closed door edge, that what they will stop the passage of smoke. They should not overly hinder the door from closing, however if the seals are too tight then they can cause an over-pressure delaying or even stopping the door from closing

-

Fire stopping & compartmentalisation for dry riser

Mike North replied to a topic in Passive Fire Protection

As long as it is stopped horizontally, no -

You need to look at BS 8214 Table 2 to 5, all suggest some form of gap that should be filled.

-

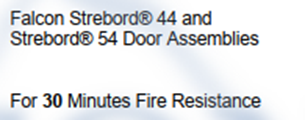

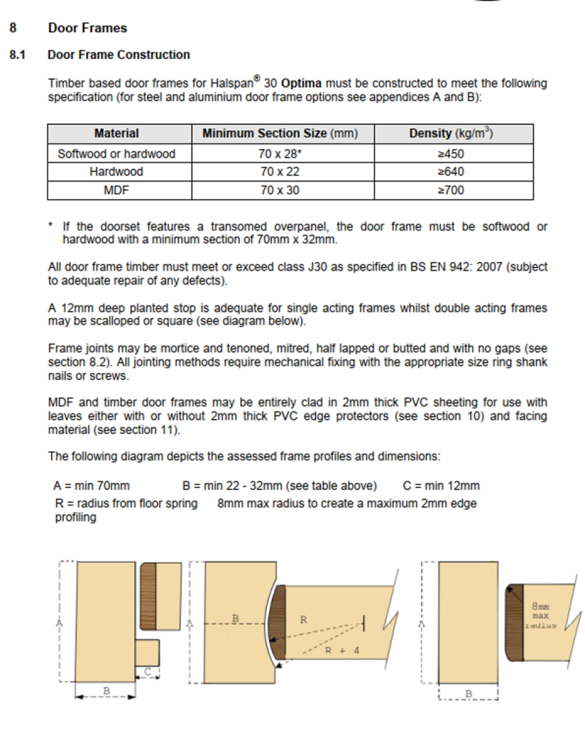

In most cases on a 30 min door pads are not required, however you must refer back to the door assessment (which obviously you can’t). For a FD30 hardwood door, personally I would forget the intumescent pads. Should I fit intumescent pads behind my fire door hinges? - Armada (armadadh.com) In many cases (but not all), the fire test assessment for the door states that for standard sized FD30 doors, intumescent hinge pads are not required. For instance the BM Trada Field of Application Report for the Strebord 44mm FD30 door core states that hinge pads are not required for doors of height 2670mm and under. Doors of height 2671mm and over need 1mm intumescent pads under both hinge leaves. Likewise, BM Trada’s Field of Application Report for the Halspan Optima 30 door core, simply says; hinge intumescent protection not required. And a third example is Jeld-Wen’s Tubeboard FD30 door core, where the Certifire Certificate of Approval also says; none required.

-

The only way to prove the door is compliant is to provide a certificate or conduct a burn test