-

Posts

388 -

Joined

-

Last visited

Posts posted by Neil Ashdown MAFDI

-

-

Regulations are not so specific as to deal with a door knocker/ornament in terms. However, the fire doors must be maintained as adequate to provide sufficient fire and smoke protection to keep relevant persons safe from the effects of fire. Whether or not the knocker/ornament is suitable for fitting to a fire door would be a matter for a fire door specialist.

-

Although not specifically mandated, it would be good practice for a competent person to inspect the new fire doors and the installation works for compliance with the relevant standards. Otherwise, how do you know they are suitable and adequate to provide the necessary fire & smoke protection? Guidance from HM Gov for fire safety in residential buildings can be found here https://www.gov.uk/government/collections/fire-safety-legislation-guidance-for-those-with-legal-duties#guidance-for-residential-buildings-under-the-fire-safety-order

-

Section 2 of this HM Gov guidance document https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/1147631/A_guide_to_making_your_small_block_of_flats_safe_from_fire.pdf covers the responsibilities of those that own/manage small blocks of flats.

Note that fire safety legislation requires a suitable and sufficient Fire Risk Assessment to be carried out and kept up to date. Checking the adequacy of the fire doors is part of that Fire Risk Assessment and the document provides guidance on this matter. Refer to page 25 for HM Gov guidance about inspection & maintenance of fire doors.

-

Building or Fire Safety?

-

Yes indeed Mike, and compliant with what?

-

I have seen similar situations in care homes. Some FD60(s) and another FD30(s) with no apparent reason for the difference in door specification. So where FD60(s) doors have been fitted, surely the question would be: 'Is the added fire resistance that these doors have, any material benefit in terms of the safety of the persons at the building and the safety of the fire services entering the building?'

-

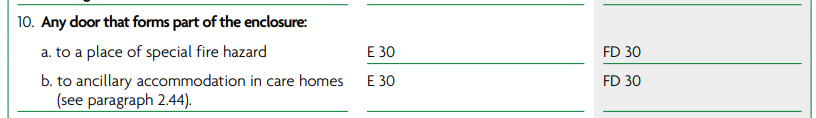

ADB Annex C Fire Doors states:

But clearly the most recent fire risk assessment should provide details of the fire rating required given the specific risk to life safety, the fire strategy and access for fire fighters.

-

Its most likely that because these are double-leaf doors, the fire resistance performance test included wider intumescent seals at the top edge to mitigate the effects of the extra width (eg. two leaves rather that one) at a point where the intensity of the heat is greater (eg. heat rises and risk of failure would likely be at the top edge and meeting edges).

The doors would be manufactured to the same specification as those that were fire tested.

-

I am not aware of any fire risk issue with plastic finger guards fitted to timber-based fire doors. This might be useful https://www.enfielddoors.co.uk/finger-safe-guards-for-fire-doors/#:~:text=Care environments&text=Adults are susceptible%2C too%2C especially,for adults with special needs.

-

Hi Tony,

All good thanks 🙂

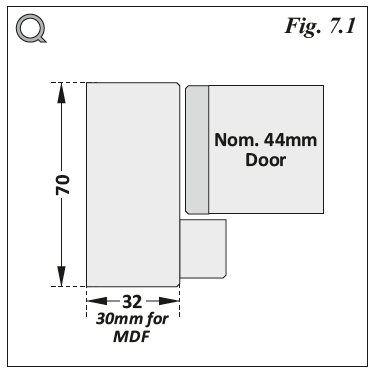

Q1) I have been looking at our companies documents on on our fire door survey sheets it requests frame thickness. What does this refer too and how would it be measured please. Again we have no certificates or O&M manual for this door. A1) The door frame thickness and material is important so that it complies with the certification for the fire door leaf but clearly without certification to refer to you can't check it. If there's a Certification label or plug on the door leaf you may be able to trace the door leaf to the manufacturer and obtain the certification. The thickness of the door frame is commonly minimum 30mm thick.

Q2) I have also noticed on one of our double leaf sets. Around the frame it has 1 x 20mm intumescent seal. Where the door meets on the closing edge it has 1 x 10mm. Surely this is in correct? Again we have no certificates or O&M manual for this door. A2) Usually there would be one 20mm intumescent seal in the meeting edge of the main leaf or possibly one 10mm seal in both meeting edges but offset, not opposing eachother. Again you need the door leaf certification to find out the exact specification.

-

Not mandatory but useful for filling gaps in untidy mortice work. The fire door leaf installation instructions/product data sheet should provide information where these are required.

-

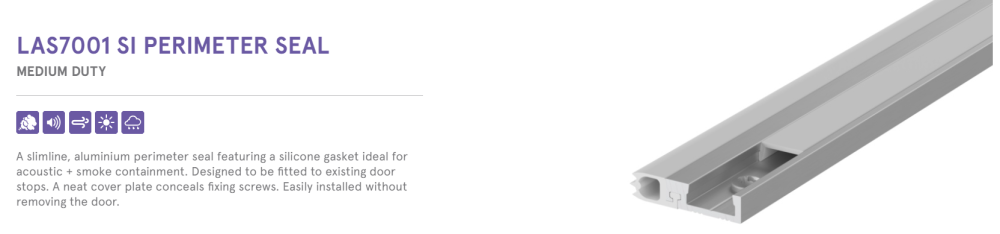

These fit to the door frame rebate stop so that the flexible seal compresses when the door leaf closes against the stop.

-

-

Assuming the door frame jambs are timber. Then insert solid timber pieces, of the same type as existing, using urea formaldehyde based adhesive to tightly plug the gaps completely with no voids.

-

Referenced in BS 8214: 2016 Timber-based Fire Door Assemblies: Code of Practice https://knowledge.bsigroup.com/products/timber-based-fire-door-assemblies-code-of-practice/standard but not necessarily a legal requirement

-

There are better ideas:

For FD30 doors the intumescent seal may be interrupted at the hinge positions (3 @ 100mm) and single lock/keep. For FD60 one of the twin the intumescent seals can be located to by-pass hinges due to the extra thickness door leaf.

For smoke sealing use a seal that is attached to the door frame rebate stop, therefore continuous without interruption.

-

This might help http://firstglass.ie/wp-content/uploads/2019/03/Pilkington-Pyroshield-Pyroshield-2-Comparison.pdf

Wired glass has traditionally been cut from larger sheets (thus no marking) and used for glazing of fire doors and screens where fire protection is required. The glass will crack in a fire but its fire rating is provided by the wire holding the glass together and this type of glass can be found widely in timber fire doors and glazed screens. In recent years the products have been improved - see Pyroshield 2 (above link) and Pyrostem https://www.pyroguard.eu/all-products/pyrostem/

The GGF guide provides best practice guidance for selecting products and installing them where 'fire rated glazing systems' are required.

-

To be suitable for a timber-based fire door the night latch needs to be Fire Rated CE / UKCA marked to BSEN12209 and of course compatible with the door leaf in question. Once the one ordered arrives we may be able to check. Good luck.

-

-

https://www.firedoorscomplete.com/training-qualification We would be please to help.

-

Thanks Mike,

Excellent, we will buy one and let you know how we get on.

-

Hi Mike, Strebord doors with Euro and oval cylinders up to 1400mm up which is good, but as you say it depends on the evidence for the door. But not for cylinder rim night latches, nada. Unfortunately.

If you find one please let me know, that would be really useful. Thanks 🙂

-

These days cylinder rim night latches are not fitted to fire doors. There are three main reasons: 1) Lack of availability of fire rated cylinder rim night latches. 2) The installation height for a night latch is usually higher on the door than permitted by the fire test evidence for the fire door leaf. 3) The lock cylinder requires a large diameter hole through the door and this may adversely affect the fire resistance performance of the door.

However, its possible that the existing door and lock combination was accepted by Building Control at the time of installation.

-

Unlatched doors are easier to use and provide a more efficient escape route. Therefore, so long as the self-closing devices are strong enough to hold the unlatched doors closed in draughty conditions I would advocate unlatched doors.

Fire doors in a domestic 3 storey house

in Fire Doors and Accessories

Posted

Three storey house? If so a compartment wall and fire door would be required to make the stairs a protected route for escape from the upper floors.