-

Posts

505 -

Joined

-

Last visited

Posts posted by Neil Ashdown MAFDI

-

-

Yes, I agree its an issue for me too.

I have some evidence of fire resistance performance for a cylinder rim night latch and it refers to fire resistance performance tests. In terms of compatibility, I would only install one where I can be certain the type of door is covered by the available test evidence including intumescent protection and location of the device. Even then I wouldn't recommend one due to issues with the self-closer often failing to overcome the resistance from the latch strike.

-

The building may have changed. "On the day" is important.

-

It would appear that the doors you describe are most likely not fire resisting doors. Has a fire risk assessment been carried out? Are these doors considered adequate for the purposes of fire protection?

-

Its not the installers job to advise exactly where fire doors are required, that is a job for the Fire Risk Assessor. There should be a Fire Risk Assessment document for the building. Consult that document for information and if there's no relevant information there discuss this with the Fire Risk Assessor via your client.

-

This looks like an edge seal of intumescent material. FD120 doors require a greater amount of intumescent edge sealing than lower rated fire doors. Is there any mark, label or plug on the door enabling traceability to the door manufacturer? If so it should be possible to answer your question by consulting them.

-

You will find that third party certificated fire door leaves specify that CE or UKCA hinges to BSEN1935 are a requirement and often certificated too. Doors fabricated from fire door blanks don't always specify TPC but might require CE or UKCA marking. Building Regulations Approved Document B (appendix C) requires hinges to have a minimum melting point of 800 deg C. https://www.gov.uk/government/publications/fire-safety-approved-document-b

-

From your comments I am unsure whether you are referring to the hardwood door lipping or the intumescent strip?

The hardwood lipping should be prized away from the door leaf only by just enough so that Cascamite adhesive can be applied to the surfaces that are to be mated. Then use small panel pins to secure the lipping whilst the adhesive dries. You can then either remove the pins afterwards or you can bury the head of the pins into the hardwood lipping and fill over the heads.

A loose intumescent strip can be secured to the edge of the door or the door frame reveal using small panel pins. https://www.ifsa.org.uk/

-

The slight damage near the mortice lock faceplate can be easily repaired, just as you would with a normal timber door. As you say, adjust the door position in its frame to achieve the 2mm to 4mm gaps.

-

Contact a suitably experienced and competent fire door inspector. They would be sufficiently confident in their decisions and be able to support their decisions with evidence or, in the case of a nominal or notional door, with valid reasoning.

-

Not a requirement but may be used. Looks much smarter when they are. The lock or latch must be suitable for the particular type of fire door in question.

-

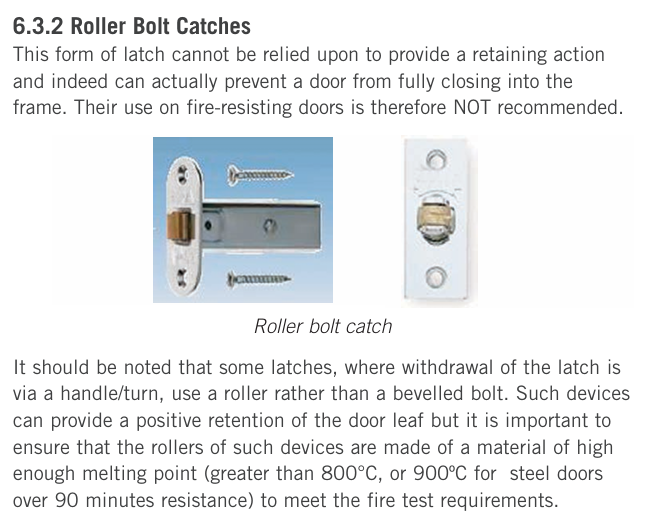

Roller bolt type latches are not usually fitted to fire doors. Section 6 of the document 'Code of Practice: Hardware for Fire & Escape Doors' deals with latches and the many fire door related issues concerned with the different types. The document is available online at http://firecode.org.uk/Code_of_Practice_hardware_for_fire_and_escape_doors.pdf

Below is particular commentary on Roller Bolt Latches

-

Hi Richard,

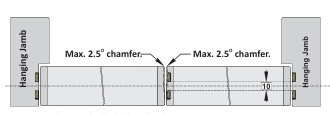

This is a common problem, installers don't always realise that fire doors have strict trim allowances. If the door has already been trimmed to its max, there's little point in trimming it further just to add timber back again.

If you can find a certification label on the door, that enables you to contact the door manufacturer for specific advice.

We provide various types of fire door related training but not specifically Responsible Person training for fire safety generally. https://www.firedoorscomplete.com/

-

Eg. Active leaf on the right, with seals fitted. Slave leaf on the left with no seals. See below:

Consult the product data sheet for the door leaf for specific requirements, if you can.

-

The intumescent seals / smoke seals should not be fitted to the same edge as the flush bolt because the interruption of seals would be too great. Fit them instead to the active leaf so that when the doors are closed the seal opposes the bolts.

-

Based on much-reading of the differing data for many different types of timber fire door construction, I would opine as follows:

1) Best practice is 6mm min thick lipping after planing-in. So 2mm residual thickness behind the intumescent seal when grooved into the door leaf edge. I have come across assessment reports permitting less than 6mm but I feel that shouldn't be relied on generally.

2) Urea Formaldehyde based adhesive is suitable for adhering hardwood lipping to timber-based FD30 & FD60 doors.

3) Cascamite is widely available from online outlets.

PS. Check thickness of door stiles before trimming. There may be no point trimming them down just to fit thicker lipping, if they are already narrow?

-

Very helpful, thanks for sharing. They seem to be the most appropriate actions and avoiding the need for replacing doors unless necessary.

-

Intumescent gaskets are required only where the product data sheet for the fire door leaf requires them.

-

Guidance can be found at https://assets.publishing.service.gov.uk/media/65e9def95b6524001af21bcc/Fire_Safety_in_Purpose_Built_Blocks_of_Flats_Guide-update.pdf

The Case Studies might prove useful as might Section 54 on Compartmentation, 55 to 59 on Means of Escape and 62.12 onwards on Fire Doors.

-

Certainly before 2003, sorry I can't be more precise. More at this thread:

-

Yes that's right. Without documentary evidence of fire performance for that type of maglock in that type of door, its up to the Fire Risk Assessor to decide about suitability on a risk-assessed basis.

-

Sign on edge (only) fails to comply with ADB. No doubt about it.

-

Approved document B

-

These 'failures' do seem extreme in my opinion and, based on what you have stated above in the case of a timber-based door, I would support the use of a fire rated wood-filler applied in accordance with its product data sheet.

-

"I was just under the impression that if this wasn't manufactured and tested this way then the void left by the magnetic locks would be too deep and long to have any suitable repair methods."

It may be that the void can be filled with suitable timber and adhesive, or replacement may be necessary. Without seeing the door assembly first-hand, its not possible to say. There are some fire door-set and maglock system combinations that are suitably evidenced. Contact some fire door-set suppliers or ask the fire door inspector for assistance.

Notional or Nominal Fire Door?

in Fire Doors and Accessories

Posted

https://www.firedoorscomplete.com/news/nominal-fire-doors-notional-fire-doors-upgrading-fire-doors The revised version of BS 8214 is due out soon, it might have a different view! Its open for comment at https://standardsdevelopment.bsigroup.com/Unauthenticated