-

Posts

390 -

Joined

-

Last visited

Posts posted by Neil Ashdown MAFDI

-

-

The gaps of 4mm to 6mm would most likely never have been compliant. The current hinges may be compliant (with building regulations Approved Document B) where the melting point of the materials they are made from exceeds 800 deg C. Each flat entrance door should be fitted with suitable smoke seals and intumescent edge seals.

So there are clearly some defects with the fire doors that may allow fire and smoke to spread from the flats and into the escape routes in a fire situation, before the minimum thirty minutes required by building regulations (ADB).

The Fire Risk Assessor at the building should decide what remedial works should be undertaken and at what priority in terms of the fire strategy at the building.

-

Not allowed because it fails to automatically release when the fire/smoke alarm is activated.

-

The issue with plastic signs stuck to the non-fire side of a non-insulating door (eg metal or glass) is that heat transfer could cause the sticker to ignite.

-

It would be a specialist product https://www.thepocketdoorcompany.co.uk/product/classic-single-fire-rated-pocket-door-system-copy-2/ rather than something you would assemble using various component parts.

-

If the defect is that the closing edge gap is 8mm, then the correct way to rectify the defect is to remove the door assembly or at the very least loosen the door frame closing jamb and reinstall the assembly or pack the closing jamb as necessary to reduce the gap to between 2mm and 4mm. Then it will be necessary to tighten all fixings maintaining correct gaps and alignment before correctly fire-stopping the gap between the door frame and the supporting wall. Refer to 'BS 8214: 2016 Timber-based Fire Door Assemblies - Code of practice' for support.

-

Based on the use of the self-closer above and assuming that the fire door leaf has evidence of fire performance in an unlatched configuration, the door could be unlatched. Correct installation of the self-closing device is key to performance for 'hold-shut' as well as self-closing performance.

-

Whilst there is no mandatory requirement for certification, fire door installers should be competent persons. https://www.legislation.gov.uk/uksi/2005/1541/article/18/made

If you are interested in fire door installation training https://www.firedoorscomplete.com/training-qualification

-

Flat entrance doors opening onto communal areas inside the block would be FD30(s) and self-closing as a minimum. Refer to BS 8214: 2016 Timber-based Fire Door Assemblies - Code of practice for guidance on smoke seals and threshold gaps and seals. https://bookshop.bmtrada.com/bookshop/view/1f43261a-1100-489d-8c5e-f4673ff17739

-

The door leaf manufacturer will advise whether such a device is permitted as well as the position for the middle hinge. The self-closer manufacturer's installation instructions will provide the details about the position of the self-closer in connection with the middle hinge.

-

-

Its a question for the 'inspector' but if you can demonstrate that you have carried out the works in accordance with the wired glass manufacturer's requirements, that should be acceptable.

https://mbp.co.uk/wp-content/uploads/2021/05/PYROGUARD-CF5954-Pyrostem-exp.20260524-rev.20210525.pdf

Above are only suggestions as we don't know which product the wired glass is and when it was made. Where you are unable to identify the glass, you should use best practice methods https://shop.ggfmembers.com/a-guide-to-best-practice-in-the-specification-and-use-of-fire-resistant-glazed-systems-ref-20-1/ and https://www.ggf.org.uk/about-the-ggf/contact/

-

Yep. In this context, better to lip the bottom rather than the top.

-

Always difficult with non-intrusive inspection and when there's no evidence. In terms of guidance https://www.local.gov.uk/sites/default/files/documents/Fire Door FAQs.pdf

-

For certainty on this matter, always contact the door leaf / door blank manufacturer for advice. There isn't much in the way of information on-line on this particular subject but this is quite helpful: https://www.falcon-timber.com/downloads/

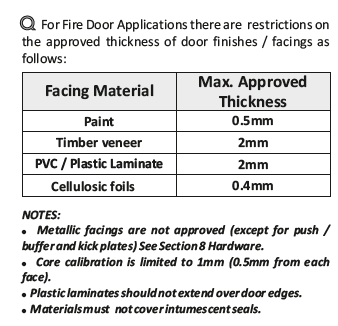

Typically guidance on applying facings might look something like this:

-

Q2). A couple of doors have maglocks that have been bolted through the door. There is no information on the door. The inspector recommends new doors as there is an integrity breach. Can maglocks be removed & door repaired? ( 2- I'll let the forum's fire door specialist address this next time he logs on ) :

A) There are some timber-based fire door / magnetic lock combinations that do have evidence of fire resistance performance. So, it may not be appropriate for the mag-locks to be removed / fire doors replaced - it would depend on the type of door leaf construction and the type of mag-lock. I would advise that first a risk assessment should be carried out to evaluate the risk to life safety and building safety were the fire doors to fail to provide their ultimate fire resistance performance as designed. Where the risk is untenable and a certificated solution is required then the fire doors should be replaced with a set that are suitable for mag-locks. If the mag-locks are no longer required and it is felt that the doors do not require certification and can be repaired - then the repairs to the door leaves and frame should be made to a joinery standard using suitable hardwood tightly fitted with no holes, gaps or voids.

-

Begin with the self-closer manufacturer, the may be able to put you in contact with a door manufacturer that has dual certification using their self-closer.

-

Yes, as you have picked up - the lipping must be flush with the face of the door. So lipping may be replaced or added to the edges of the door but the hardwood must be of the correct dimensions, species, density and fitted with the correct adhesive. This type of 'repair' is very likely to fall outside the scope of the fire resistance performance certification for the door and therefore the certification would become invalid.

-

Before you fill that gap with intumescent or non-combustible material check that:

The fire door leaf does not sit proud of the door frame at any point.

Have the hinges been checked for compatibility with the fire door leaf, in terms of fire rating and dimensions?

Are these 'extended butts', are the fire doors intended to open to 180 deg?

-

-

The product data sheet or installation instructions for the door leaf will advise what materials are permitted for the door frame.

-

As Nick T says above, the thickness of the hardwood lipping would very likely be outside the scope of the door's Assessment report for fire resistance were they carrying any evidence of performance. You state that the door is a Nominal fire door which means in the opinion of the 'competent person' that the door has the attributes of a fire door but that there is no evidence of fire resistance performance.

Therefore, whilst it is likely that the door could be non-compliant to its original manufacturer's 'certification' there is no documentary evidence to confirm this in absolute terms. I would advise the Responsible Person to risk assess in terms of how critical are the fire doors to life safety and building safety should they fail to provide their ultimate required fire resistance performance.

Also, the gap between the door top edge and the underside of the door frame head appears to be excessive. Generally, it should be between 2mm and 4mm so there could be an issue with cold smoke spread as well as fire resistance performance.

Also, the door-closer arm configuration is incorrect. The adjustable arm should be at 90 deg. to the door frame head with the tensioning-arm canted over accordingly. Remediating this will very likely improve the door-closer performance.

-

These signs are designed so that the lollipop shaped blue coloured sign is conspicuous when the door is open. Eg: when there is potential for danger. Consult the document: Code of practice. Hardware for fire & escape doors, section 10 deals with signs, at http://firecode.org.uk/Code_of_Practice_hardware_for_fire_and_escape_doors.pdf

-

Consult the 1990 version of the standard BS 8214 Timber-based fire door assemblies - Code of practice. https://knowledge.bsigroup.com/products/code-of-practice-for-fire-door-assemblies-with-non-metallic-leaves/standard

-

Looks like a composite construction flat entrance door and looks similar to one I have seen before by Manse Masterdoor. What makes you believe the core is solid timber?

Glass Fire Door??

in Fire Doors and Accessories

Posted

Looks like a timber-panel door and therefore most likely not traceable to evidence of fire resistance performance. Your next 'go to' would be technical fire resistance performance data for the glass itself and most GWPP would most likely have been manufactured by Pilkington as the product 'Pyroshield' or its forerunner. Many would accept this type of fire door as 'Nominal or Notional'.

Where you cannot satisfy yourself of suitable product performance, a Fire Risk Assessor should be able to advise in terms of the suitability of a fire door with unknown ultimate fire performance given the location of the door and the fire strategy at the building.