-

Posts

390 -

Joined

-

Last visited

Posts posted by Neil Ashdown MAFDI

-

-

That's useful to know, Anthony. Do you have link (and page/section number) to the gov guidance document?

-

From what you say it seems clear that area of the house could be at risk from the effects of a fire in the garage. I would consult the housing department at your local authority on this matter.

-

Yes the entrance door to your flat should be fire resisting and with restricted cold smoke spread.

-

Its actually BS 7352 Grade 8 dating back from the 1990s. In those days, prior to its replacement BS EN 1935 2002, that type of hinge would have been used for Fire Doors. If the hinge is damaged or worn then replace all hinges on that door with their modern equivalent to BS EN 1935 minimum Grade 11

-

-

I have inspected many fire doors to stair and lift lobbies at blocks of flats. Some older blocks have doors without vision panels but clearly a door in such a location is safer for the user when there's a vision panel.

-

The main issue is that a standard intumescent air transfer grille will not restrict the spread of cold smoke. Also, installation of such a device should be done by a competent person so as to ensure the door's fire integrity performance is not compromised.

If the door in question opens on to an escape route, there is a risk that cold smoke from inside (in a fire event) may impede persons attempting to use the escape route. Your fire risk assessment should note this and recommend action accordingly.

-

In my view, the mirror is rather large and heavy. I would not recommend fitting such a mirror to a fire door due to risk of causing twist to the timber door leaf. Much better on the wall or maybe a wardrobe, if possible.

-

What size are the screws? Where on the door are you fitting the mirror (will it be near the door edges) and how big and how heavy is it? What have the block owners/mangers said about this?

-

My understanding is that the doors are FD30s fire resisting doors. Are the rack bolts compliant with paragraphs 6.2.2 and 6.2.3 on page 61 of the document 'Hardware for Fire & Escape Doors' ?

-

So the door will be a FIRE DOOR KEEP LOCKED and kept locked at all times. The door should be fitted with a fire rated mortice lock and a 'Fire Door Keep Locked' sign to the outside. I assume the door is made from timber based materials.

The document 'Hardware for Fire & Escape Doors' at http://firecode.org.uk/Code_of_Practice_hardware_for_fire_and_escape_doors.pdf provides the information you need on pages 60 to 68.

-

Looking at this from the fire door survey point of view. The British Standard for timber-based fire door assemblies (BS 8214) states no requirement with regard to floor coverings at the threshold.

Installing a threshold strip to the floor is always preferable as it helps meet compliance with door leaf to floor gap requirements. BS 8214 and BS 9999 refer.

-

The requirement in terms of threshold gap for a timber based fire door is 3mm max where the door also provides restricted smoke spread. Where restricted smoke spread is not a requirement the max gap is nominally 10mm (sometimes less depending on test evidence).

More than 100 is a lot of fire doors (for an industrial premises) so one would ask whether they all really need to provide fire and smoke separation?

The building operator should have carried out a fire risk assessment and should carry our periodic fire evacuation drills. From having conducted those a fire strategy document should be available and if it contains sufficient information it should provide details of the locations and ratings of the fire doors.

Once you have established which doors are necessary to the fire strategy you will need reference documentation on which to base your upgrading works. A good start would be these two:

BS 8214:2016 Timber-based fire door assemblies - Code of practice https://shop.bsigroup.com/ProductDetail?pid=000000000030332501 and Code of practice, Hardware for fire & escape doors http://firecode.org.uk/Code_of_Practice_hardware_for_fire_and_escape_doors.pdf

-

Utility room to garage door should be FD30s. Check 'Building Regulations Approved Document B Dwelling Houses' https://www.planningportal.co.uk/info/200135/approved_documents/63/part_b_-_fire_safety

-

Hi Steve,

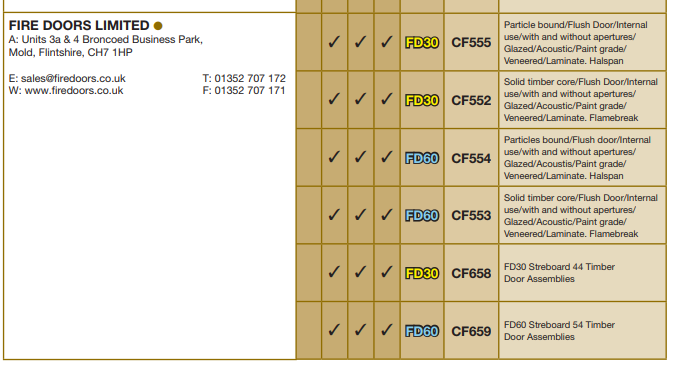

Having checked at the BWF website https://www.bwf.org.uk/wp-content/uploads/fdd/Firedor_lit/FDS_Certified_Manufacturers.pdf you can see (below) that, referencing the CF658 Certifire certificate the door manufacturer is Fire Doors Limited.

If there's a BWF-Certifire label on the top edge or hanging edge of the door leaf it should carry the CF number, the name of the door manufacturer and another number with the prefix A. This provides traceability back to the door manufacturer. If the manufacturer refuses to provide any evidence of fire performance (I don't understand why they wouldn't though) you can access the technical manual and certification for the Strebord door core at https://www.falconpp.co.uk/technical/

-

The suspension on the production of composite construction fire resisting doors has been lifted. I suggest you contact the Association of Composite Door Manufacturers at http://acdm.co.uk/ for advice.

There are also composite construction fire resisting doors on the market that are covered by the Certifire certification scheme and you can find member companies at https://www.warringtonfire.com/certified-companies/certifire

-

Thanks for the pic. Makes it so much easier to understand the issue.

In my opinion if the seals are as close to each other as is possible, whilst still allowing the door leaves to self-close without binding on the edges of the seals, then that's as good as you will get.

That is assuming the seals will not fit to the pull side of the doors.

Just another thought, have you checked with the seal manufacturer for advice? They will, I expect, have tested the seals for restricted smoke spread to either BS 476 part 31.1 or BS EN 1634-3. So it would be interesting to see if that test was done on double leaves or single leaf..........or both!

NB: Automatic drop-down threshold seals are also available to fit into a groove in the door leaf bottom edge.

-

-

Is the blade of the threshold seal continuous along the full length of the door bottom edge?

-

"2) Should there be brushes at the bottom of the fire door (he has done strips on the sides and top)"

The door should restrict the passage of 'cold-smoke' in accordance with BS 476 part 31.1 or BS EN 1634-3. So either the gap at the threshold should be a maximum of 3mm or it can be 10mm max (generally, depending on door test evidence) but with a suitable threshold smoke seal brush fitted.

"3) Should building control be involved, or do the doors need to be certified/checked in some way once installed?"

You have an obligation to ensure the new fire doors you fit will meet the required standard for fire and smoke protection. This document may be useful https://www.local.gov.uk/sites/default/files/documents/fire-safety-purpose-built-04b.pdf

-

"My flat is on the ground floor, with a private entrance into my own front garden however as I am the end block my flat is next to the staircase that leads upstairs".

From what you say, it seems this is the only entrance/exit door from the flat. So the question is: If there was a fire inside your flat would failure of the door to hold back fire and smoke prevent others from using the staircase to escape from the floors above?

FD30s composite flat entrance doors are available so speak to your supplier if necessary.

-

Doors to flat entrances should be FD30(s). This means fire and smoke seals should be fitted at the top edge and both vertical edges, the smoke seal should just about fill the gap between the door leaf and door frame without causing hindrance to the self-closing action.

The gap requirement at the threshold is 3mm maximum, for a fire door that should provide cold smoke protection.

On fitting a hardwood lipping to the door bottom edge to reduce the gap, this depends on whether or not this is permitted by the door manufacturers' installation instructions/product data sheet. Check with the door manufacturer as to whether or not such work will void any fire performance certification applicable to the door leaf.

-

Using thin pieces of timber to add thickness to the inside face of a door frame or to the edge of the door leaf is not a suitable repair (to a fire door) when trying to reduce the gap between the door leaf and frame.

Where the gap is so large that it cannot be reduced by adjustment, either:

1) Loosen the door frame jamb, pack behind and fire-stop between frame and wall accordingly. So as to reduce the overall width to suit the door leaf.

2) Remove the existing hardwood lipping form the door leaf and fit a replacement hardwood lipping thick enough to reduce the gap. Lippings should be generally min 6mm thick to a max of 18mm

I assume suitable intumescent seals are fitted?

-

Hi Karen,

"Certificate the door" is the wrong phraseology and demonstrates a lack of understanding about fire doors. Certification relates to fire doors and component products where the manufacturer is a member of a third party certification scheme.

My advice is to have the fire door inspected by a Certificated Fire Door Inspector, after inspecting the door they will issue an inspection report. The report will either list the fire door as compliant or if there are any compliance issues the report will include details of the remedial work required. https://fdis.co.uk/find-an-inspector/

The council should accept the inspector's report as evidence of compliance, assuming of course that the fire door is indeed compliant.

double swing hinges on a fire door

in Fire Doors and Accessories

Posted

Best solution is to fit floor springs and pivots. See page 39 of the document Hardware for Fire & Escape Doors - Code of practice http://firecode.org.uk/Code_of_Practice_hardware_for_fire_and_escape_doors.pdf