-

Posts

490 -

Joined

-

Last visited

Everything posted by Neil ashdown

-

A double-action swing door would be unlatched and the self-closing device / floor spring should cause the door to close in the correct position. If its a fire door, bear in mind not all standard fire doors are suitable for double-action.

-

The office being a habitable room should have the same level of fire compartmentation as the rest of the house. So yes a fire door would be required between the office and garage. Have you considered how you might escape from the office without using the garage?

-

Fire Door Certification Stickers

Neil ashdown replied to Steve AU's topic in Fire Doors and Accessories

All new fire doors must have documentary evidence of fire resistance performance but they don't have to have labels or plugs. So ask the supplier or manufacturer to provide it. -

Advice given earlier is based on relevant guidance. I am not aware of any guidance to support adding thin strips of timber to the inside face of the door frame for reducing the gap, as an alternative to reinstalling the door frame.

-

Sorry, can't help you on that one.

-

There is no guidance that thicker rebate stops mitigate the effect of excessive door to frame gaps. Where restricted cold smoke spread is a requirement, effective smoke seals will be necessary.

-

Contact R&T technical at https://www.ratman.co.uk/contact/

-

Fire doors in a domestic 3 storey house

Neil ashdown replied to a topic in Fire Doors and Accessories

This is a question for Local Building Control. https://www.gov.uk/building-regulations-approval Myself, if I were replacing doors I would use that opportunity to fit fire rated ones. -

Excessive gap on hinge side of fire door

Neil ashdown replied to a topic in Fire Doors and Accessories

Lipping depends on what fire performance certification exists for the door. I like lipping done correctly, but carrying out such work on site may void the door's third party certification. -

The hold-open device must release the fire door to self-close completely when the fire/smoke alarm is activated. This should be checked weekly when the alarm is tested.

-

Excessive gap on hinge side of fire door

Neil ashdown replied to a topic in Fire Doors and Accessories

There is no quick and easy way to do this. Remove the door and loosen the door frame fixings so that the door frame hanging jamb can be moved-over and then re-install. You will need to check the gap between the surrounding wall and the doorframe is correct and make good the fire-stopping between the wall and door frame. Depending on the gap issue, you may have to completely remove the door assembly and re-install. -

Contact the hinge manufacturer for advice.

-

I would advise that a floor survey be carried out to ensure it is suitably level for a concealed automatic threshold drop-seal to be fitted.

-

I would advise your employer to carry out a risk assessment for this issue. If it is felt that there exists a risk of a person being trapped inside then the lock should be changed to provide for keyless egress.

-

How much experience is needed to modify fire doors

Neil ashdown replied to a topic in Fire Doors and Accessories

Whilst there is currently no legal requirement for fire door installers and maintainers to possess a dedicated qualification, competence is necessary. The Regulatory Reform (Fire Safety) Order 2005 requires those that provide fire safety related services to be ‘Competent Persons’. Approved Document 7 of the Building Regulations covers workmanship and materials. Many clients such as housing associations, healthcare organisations and education providers now require that those that install or maintain fire doors have a qualification or certification as proof of competence to perform those works. Subsequent to the Hackitt Report there are industry led working groups looking at what competence should look like and you may find the recent report ‘Setting the Bar’ interesting at https://cic.org.uk/setting-the-bar-annexes.php -

Fire Door Maintenance in Buildings under 1 year old

Neil ashdown replied to a topic in Fire Doors and Accessories

There is also Regulation 10 applicable to multi occupancy residential blocks above 11 metres in storey height https://www.gov.uk/government/publications/fire-safety-england-regulations-2022/fact-sheet-fire-doors-regulation-10 -

Fire Door Maintenance in Buildings under 1 year old

Neil ashdown replied to a topic in Fire Doors and Accessories

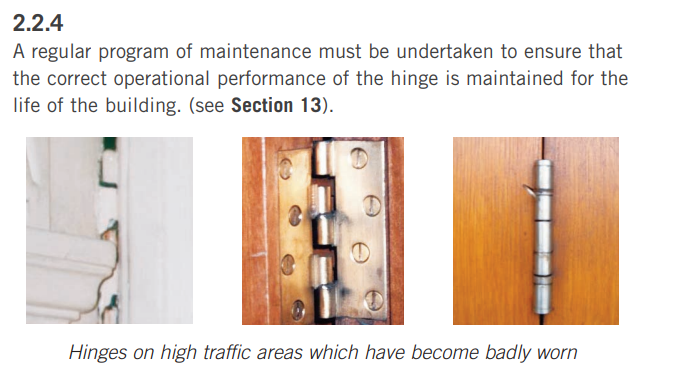

Assuming the doors are timber-based, BS 8214: 2016 Timber-based Fire Door Assemblies - Code of practice section 13 recognises that doors "do deteriorate" and says that "It is important, therefore, for inspection, maintenance and repair of any damage be undertaken on a regular basis if the fire resistance is to be maintained". -

space between fire door frame and opening

Neil ashdown replied to a topic in Fire Doors and Accessories

40mm / 50mm gaps are too large to be filled. Assuming the door assembly is timber, refer to section 9 of BS 8214: 2016. I would reduce the gap to 20mm max using tightly fitted solid timber lining screw fixed to the back of the door frame. The lining must be continuous, full width and of similar material to the existing door frame. Alternatively, you could install a new door frame. -

In terms of cold smoke, probably not. Do the doors have cold smoke seals and intumescent fire seals fitted?

-

This depends on the type, size and position of the concealed self-closing device. From what you say about the advice given by the certified carpenter it seems you may be referring to an uncontrolled Perko type chain-closer with a small footprint? If its a controlled device (with a much larger footprint) it could be that the certified carpenter is advocating that the door can be returned to a suitable condition if the concealed self-closer is removed and the void completely and tightly filled, to a high standard of workmanship, with the same materials as the door is made from. In this case, the repair would most likely be outside the scope of the door manufacturer's certification and therefore such certification would be void.

-

did fire doors before 2000 require fire rated hinges?

Neil ashdown replied to a topic in Fire Doors and Accessories

Remove the surplus oil. Then monitor the condition of the hinges and where there is evidence of wear / separation at the bearings replace the complete set. http://firecode.org.uk/Code_of_Practice_hardware_for_fire_and_escape_doors.pdf -

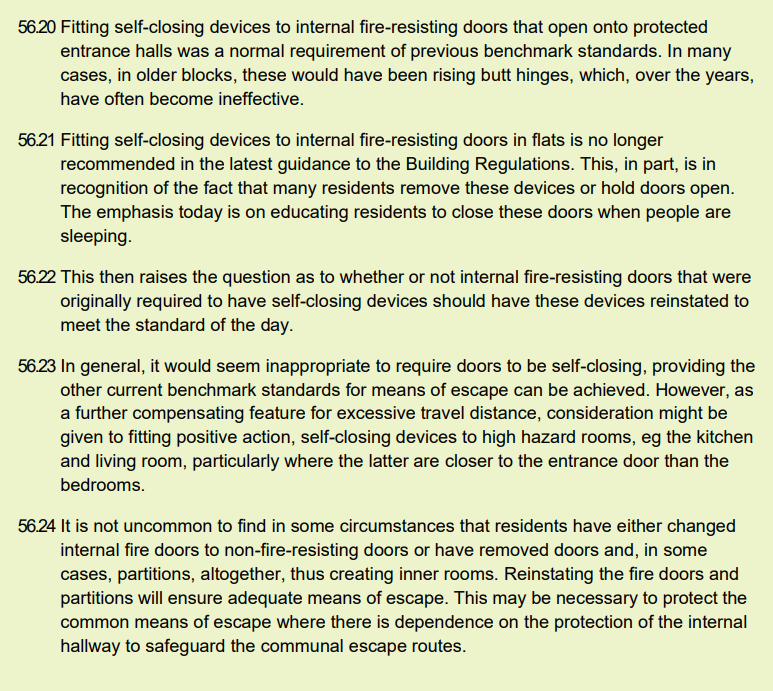

Do my fire doors need to be self closing?

Neil ashdown replied to a topic in Fire Doors and Accessories

https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/1020410/Fire_Safety_in_Purpose_Built_Blocks_of_Flats_Guide.pdf -

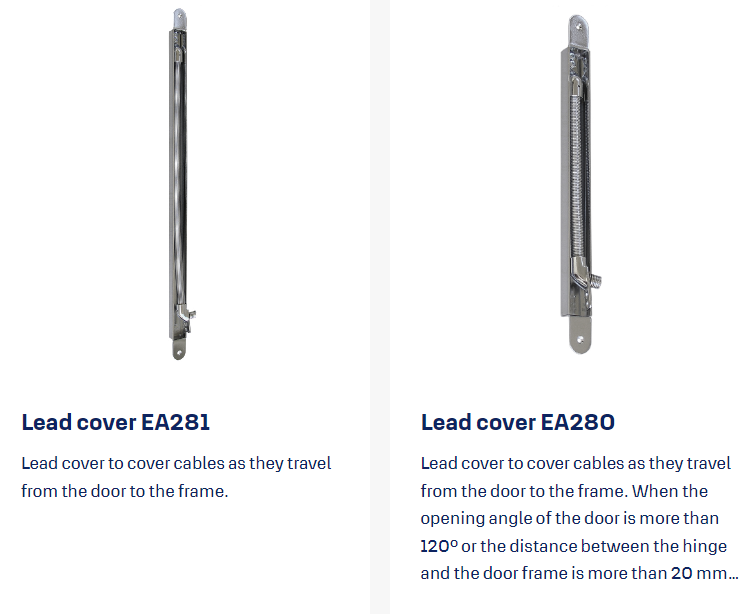

It's a lead cover https://www.abloy.com/gb/en/products/wired-locking/electric-locks/accessories/cable-ea210 and commonly used where a cable is required for an electric lock/strike. In terms of whether its allowed on a fire door, as fire doors must have evidence of fire resistance performance including the components fitted to them, you would need to consult the fire door manufacturer.

-

Converting Non Fire Rated Doors for Internal Use

Neil ashdown replied to a topic in Fire Doors and Accessories

The door to be upgraded would require inspection by a competent person before recommending upgrading products and materials. -

In the UK, various materials are used for the core of a fire resisting door. The most common is timber and/or chipboard but some composite fire doors have a core of foam within a timber frame. Metal fire doors are also available. British Standards for fire doors are for fire resistance performance tests rather that construction materials. Refer to BS 476 part 22 : 1987 and BSEN 1634-1 : 2014