-

Posts

505 -

Joined

-

Last visited

Everything posted by Neil Ashdown MAFDI

-

Bespoke veneered internal FD30 fire doors

Neil Ashdown MAFDI replied to a topic in Fire Doors and Accessories

The door blank manufacturer / supplier will be able to provide you or your door fabricator with the 'Technical Manuals' and field of application reports detailing the permitted dimensions, permitted veneer thickness, lipping requirements, seal requirements, ironmongery/hardware requirements and installation tolerances. For example: https://falcon-timber.com/downloads/ -

The usual required threshold gap for a typical timber-based fire door is 10mm max. It may be possible to reduce your 20mm to 25mm gaps by fixing a threshold plate to the floor or a hardwood lipping to the door bottom edge - you will need to survey each door and floor area to decide which (possibly both) is appropriate. A threshold plate may, of course, present a trip hazard. Assess the hazard. Where restricted smoke spread is a requirement, it may be necessary to install a flexible seal to close the threshold gap in the door-closed position.

-

We would always repair where possible. We have some Leaderflush certification data sheets and installation guide that may include configuration for intumescent seals at meeting edges. If of interest you can contact me via www.firedoorscomplete.com

-

You could check the 1990 version of BS 8214.

-

If using pins be careful to avoid ironmongery fitting positions and bury them as deeply as possible. Make sure the adhesive you use matches the requirements of the evidence of performance (field of application report) for the door leaf / door blank / door core.

-

Check the evidence of fire performance for the chosen sealant used at that gap with that frame material and wall substrate.

-

Do door stops have to be of particular thickness?

Neil Ashdown MAFDI replied to a topic in Fire Doors and Accessories

In terms of security, a solid door frame section rebated to suit the door leaf would be better than planted.- 11 replies

-

- door stops

- fire door

-

(and 1 more)

Tagged with:

-

Fire Doors & Frames

Neil Ashdown MAFDI replied to richardinnorwich's topic in Fire Doors and Accessories

There are several types of designs for timber based fire doors, most will have lipping requirements but there are some without lipping. Where lipping is a requirement, density and thickness will be specified by the data sheet for the door leaf. As for trim allowances, fire door leaves can have different core construction types some having stiles and rails and some without. Some having a tubeboard core and some being completely solid. That's why there are variations in permitted trim allowances. Select the fire door leaf most appropriate to its end use. There is no 'one size fits all' when it comes to installation. The data sheet for that particular fire door leaf will provide the necessary details but you will also find BS 8214: 2016 invaluable for guidance. A new version of that Standard is due out this year I believe. -

Gaps under FD30S doors and other matters

Neil Ashdown MAFDI replied to Bryan's topic in Fire Doors and Accessories

I would advise you to have the door inspected by a competent fire door inspector and then to contact your housing provider accordingly. https://afdi.org.uk/category/find-a-fire-door-inspector/ -

Repairing holes in fire doors

Neil Ashdown MAFDI replied to Mr Burns's topic in Fire Doors and Accessories

Yes some holes in timber fire door leaves can be repaired using tightly fitted hardwood and suitable adhesive. Clearly, any product certification for the door will be void but if certification is required a maintenance & repair contractor belonging to a relevant certification scheme may be able to certificate their work. Also, worth checking with the door manufacturer whether the magnetic lock is permitted under the scope of their certification/field of application report. -

FD30s intumescent smoke / fire strips

Neil Ashdown MAFDI replied to a topic in Fire Doors and Accessories

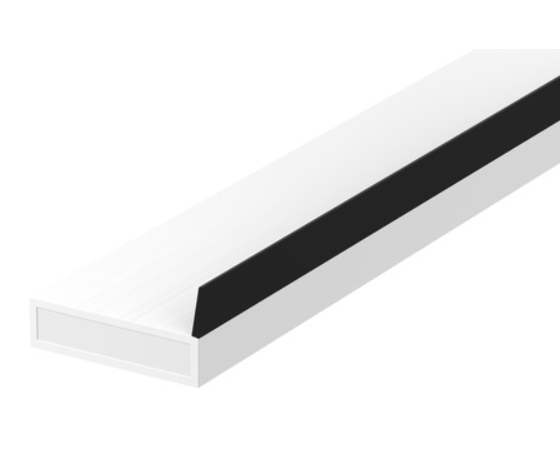

Other types of smoke seals are available. These types will make it easier for the door to self-close. https://www.lorientuk.com/products/architectural-seals/perimeter-seals -

This refers to the checks to satisfy Regulation 10 of the Fire Safety (England) Regulations 2022 https://www.legislation.gov.uk/uksi/2022/547/regulation/10/made But if your property is not in-scope there is still a requirement to ensure your fire doors are suitable and in good condition, refer to Article 17 of the Fire Safety Order https://www.legislation.gov.uk/uksi/2005/1541/article/17

-

Are specific fire door gaps a legal requirement?

Neil Ashdown MAFDI replied to a topic in Fire Doors and Accessories

The gap between the door and frame should (generally) be between 2mm and 4mm. The gap should be measured at the point central to the thickness of the door. Also, you are measuring from the surface of the door edge to the surface of the door frame. So disregard the smoke seal when measuring the gap. To be effective, the smoke seal brush or blade must lightly contact the surface that it sweeps or presses against. Hope this helps. -

The requirement in BS 8214: 2016 is that the flexible strip seals the gap. No mention of the flooring material.

-

The recommendation is that hinges for fire doors are minimum Grade 11 to BS EN 1935. Most certificated fire doors require that hinges are CE or UKCA marked in accordance with that Standard. Details in the guidance document Code of Practice: Hardware for Fire & Escape Doors. https://www.firecode.org.uk/

-

Answers to your questions: My Q’s are: Q1) Can intumescent strips fix the top and sides? A1) Gaps stated in BS 8214: 2016 Guidance are 2mm to 4mm. So remediate to achieve those gaps and fit suitable seals. Q2) Is the gap at the bottom/threshold acceptable? A2) Threshold gap for a fire door is usually 6mm to 10mm (depending on door manufacturers specification), but if smoke restriction is required the max gap is 3mm as stated in BS 8214: 2016 Guidance . If 3mm cannot be achieved a flexible seal should be fitted to seal the gap.

-

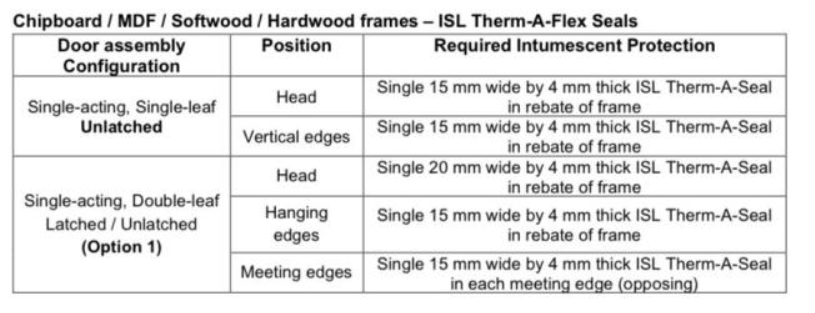

So looking at this. Opposing seals are permitted, so one could be fire only and the other could be fire and smoke.

-

I haven't yet come across a timber fire door that permits opposing intumescent seals, in the meeting edges of double leaves they would be offset rather than directly opposed. Except for doors with edge protectors that is. You could try https://www.ifsa.org.uk/

-

Thanks. Good to know about the Health & Safety (Safety Signs & Signals) Regulations 1996

-

My advice would be to: Establish that the doors are solid core and in suitable condition, record your findings. Add suitable BSEN1154 compliant self-closing devices and make sure all doors self-close completely, reliably, smoothly and without risk of causing a 'trapping injury' - of fingers etc. Add intumescent fire seals and perimeter smoke seals. Make sure the door to frame gaps are between 2mm and 4mm (within reason). Replace the existing letter plate with a fire and smoke rated item and attend to the door threshold so that it will restrict the passage of smoke in a fire. UK Government advice about fire doors can be found at https://www.gov.uk/government/publications/fire-safety-england-regulations-2022-fire-door-guidance/fire-safety-england-regulations-2022-fire-door-guidance

-

I would advise Fire Exit Keep Clear signs on both sides. The existing PUSH sign should be sufficient unless the Fire Risk Assessment requires illuminated signs.

-

Fire doors shutting loudly in HMO below

Neil Ashdown MAFDI replied to a topic in Fire Doors and Accessories

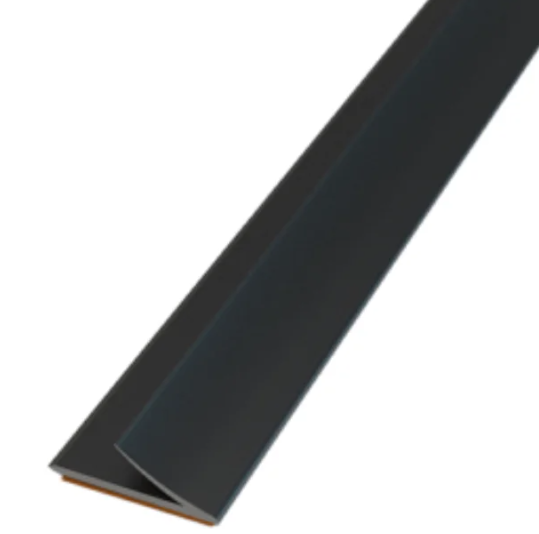

Hush pads might affect the smoke seals fitted to fire doors. Its not your door so this might not be any use to you but there are smoke seals that soften the closing action of the door - such as these: -

FD30s intumescent smoke strips

Neil Ashdown MAFDI replied to ELG Paul's topic in Fire Doors and Accessories

The face of intumescent strip should be flush with the surface of the door leaf edge or door frame. So making a deeper groove is not an option. To reduce friction as the door self-closes, you could use alternative smoke seal types such as those with a blade or you could use perimeter seals or seals fitted to the face of the rebate stop.