-

Posts

505 -

Joined

-

Last visited

Everything posted by Neil Ashdown MAFDI

-

I would take issue with the company. The frame is already grooved, so clean-out the groove for the seals to fit.

-

The mag-lock appears to interrupt the intumescent seals in the head of the door frame for some distance. If it does, I believe the surveyor is correct to recommend removal and suitable repairs. Ask the surveyor to provide a specification for a compliant repair.

-

If you engage a sufficiently competent fire door inspector/consultant beforehand they will be able to inspect the existing flat entrance door and issue a report on its current compliance status including a list of defects and recommended remedial actions. You can then engage your carpenter to carry out the works or supply and fit a new door on the understanding that payment will be released after sign-off by the competent inspector/consultant. A list of fire door inspectors can be found at https://afdi.org.uk/category/find-a-fire-door-inspector/

-

Is this a fire door?

Neil Ashdown MAFDI replied to Dragos Rusu's topic in Fire Doors and Accessories

Looks like this door in not fire rated. Does it need to be? -

Contact a competent door specialist for an inspection and subsequent remedial works. You could insert suitable hardwood and adhesive to fill those gaps but better to have the door inspected professionally so that you know exactly what type of defects exist and the necessary repairs.

-

Fitting seals to existing fire doors without

Neil Ashdown MAFDI replied to JohnSur's topic in Fire Doors and Accessories

First thing to check is that intumescent seals are not already fitted, concealed behind the lipping of the door leaf. Once you've checked that seals are actually required you could remove the door and then router grooves around the top and vertical edges of the door leaf and fit the seals tight and flush within the grooves. Seals are self-adhesive and must be an intimate fit in the groove so you won't need adhesive or pins. Do not mix different types of seal. -

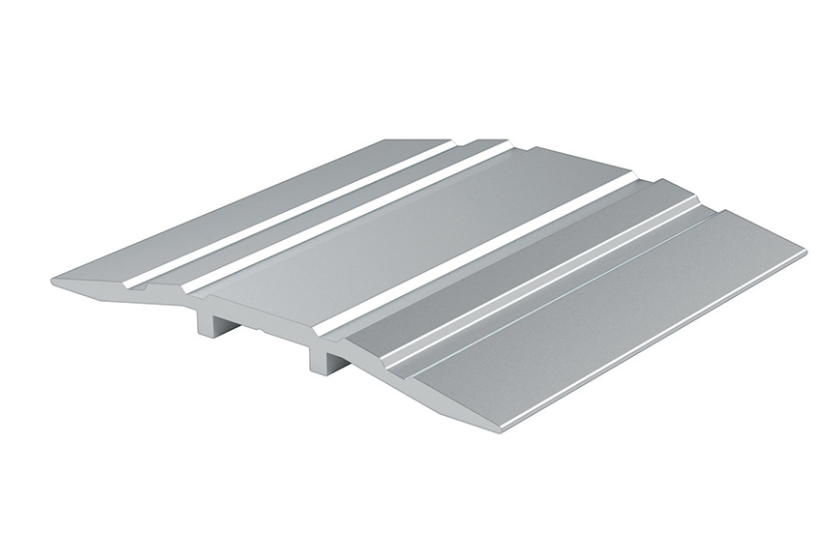

The issues with excessive (more than 10mm) threshold gaps are: 1) that the ultimate fire resistance performance for the door can be compromised because the door can drop further (in a fire attack scenario) to the floor thus opening up a large gap at the top of the door. 2) that the increased flow of air under the door can help to feed the fire thus making it potentially more dangerous 3) that an increased spread of smoke under the door could reach sleeping accommodation and escape routes with potentially highly dangerous consequences. The gap for restricted spread of cold smoke should be 3mm max or it should be closed with a flexible seal, refer to BS 8214: 2016. To resolve these issues, you could fix a suitable hardwood lipping to the door bottom edge and/or fix a threshold plate to the floor. Fit threshold seals where necessary for smoke protection. But first survey each door to decide the most appropriate action.

-

Fixings within a fire door

Neil Ashdown MAFDI replied to Matt 12345's topic in Fire Doors and Accessories

You could remove the seals, insert the fixings and fit new seals. The presence of the existing fixings shouldn't void the door certification, but check with the manufacturer. -

If there is a hole penetrating through the thickness of the timber-based door leaf, then I would make a repair by using tightly fitting hardwood dowel and urea formaldehyde based adhesive.

-

Fixings within a fire door

Neil Ashdown MAFDI replied to Matt 12345's topic in Fire Doors and Accessories

The fire door leaf manufacturer's installation instructions will state the requirements for frame fixings. The seal's don't have to be in the groove behind the seals, but are often fitted at that position because its easier to achieve the 2mm to 4mm perimeter gaps that way. And of course the fixings are concealed once the intumescent seals are installed. You could remove the seals, insert the fixings and fit new seals. -

Fire door full frame

Neil Ashdown MAFDI replied to Dragos Rusu's topic in Fire Doors and Accessories

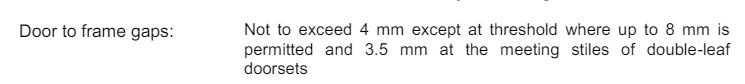

Noting that the bottom part of the door frame has an intumescent edge seal, I would work on a 2mm to 4mm gap. Have you checked with the door leaf or door-set manufacturer? It would be interesting to see what they require. -

This usually becomes an issue because manufacturers of timber-based fire doors tend not to use night latches for burn tests and that night latches are not CE or UKCA marked. Except for new doors with multi-point latching & locking, flat entrance doors would usually be fitted with a mortice sash lock with a euro cylinder including a thumb turn for keyless egress. If you can trace the door to its manufacturer you can contact them for information about the fitting of two mortice locks. I am aware of evidence of performance for two deadlocks fitted to a timber fire door, but depends on core construction, position of lock, lock-case dimensions and the necessary fire rating of the door. Which might not be FD60? This guidance might be useful too: http://firecode.org.uk/Code_of_Practice_hardware_for_fire_and_escape_doors.pdf

-

Recent HM Gov changes to fire safety regulation has not included any change to perimeter gaps around fire door leaves. You could look for marks, labels or a plug on your door to identify the door to it's manufacturer and obtain the certification data sheet. That document would state the gap requirement for compliance with the fire resistance performance certification. eg: Furthermore, the Timber-based Fire Door Assemblies - Code of practice 2016 is a guidance document that recommends a 2mm to 4mm gap - see section 9.5.2 https://knowledge.bsigroup.com/products/timber-based-fire-door-assemblies-code-of-practice?version=standard

-

Fire Door Inspection Flat Entrance

Neil Ashdown MAFDI replied to Bankside1984's topic in Fire Doors and Accessories

Don't remove and replace the recessed intumescent strips unless they are damaged or unsuitable. The bat-wing seals if in good repair and fitted correctly should be sufficient as smoke seals. Replace them if necessary and ensure that the seal closes the gap between door frame stop and the face of the door leaf when closed. Examples of easy to fit seals below: -

Fire door regulations of pre 2000

Neil Ashdown MAFDI replied to david wood's topic in Fire Doors and Accessories

Some composite flat entrance fire doors from that period had metallic faces with timber stiles and rails and the core filled with foam. In my experience these types of doors do not carry any marks and the hinges (as apart of the door-set) or evidence of certification but they may still be fire doors. If you require confirmation of likely fire performance, you could engage a fire door inspector that has wide experience with composite fire doors. -

Flat front door threshold gap dispute

Neil Ashdown MAFDI replied to IanS's topic in Fire Doors and Accessories

BS 8214: 2016 requires that a flexible threshold seal, where fitted, seals the gap. Alternatively, the maximum gap is 3mm. -

A surface mounted door bottom seal can be used. But make sure the door doesn't stick on the floor covering and fail to self-close.

-

Assuming removal of the Aquamac seal and then moving the hinges inwards into the door frame jamb would resolve the issue. Do that, as it should not cause the door certification to be void. The reverse side of the hinge blades should not be visible. Obviously an alternative seal will be required but these are available.

-

Remedial repair 2-4mm gap

Neil Ashdown MAFDI replied to Althetaff's topic in Fire Doors and Accessories

Our usual advice would be to loosen and pack the door frame jamb to resolve the gap issue. If you prefer not to do that you could contact the distributors for FrameFit to check this product's suitability for your door. -

I am informed that there is no relevant Standard for this type of lock and that therefore CE or UKCA marking is not possible. If you can trace the fire door to its certification or its manufacturer you should be able to check what type of locks are permitted.

-

Fire door regulations of pre 2000

Neil Ashdown MAFDI replied to david wood's topic in Fire Doors and Accessories

Are the doors composite construction flat entrance doors? -

Depends where the door is located. A) Is the door inside the flat/house? B) Is it a flat entrance door? C) Is it a door from inside the house to an integral garage? Refer to Code of Practice: Hardware for Fire & Escape Doors section 3 'door closing devices'. http://firecode.org.uk/Code_of_Practice_hardware_for_fire_and_escape_doors.pdf If it's B or C it should be a 'controlled' self-closing device.

-

Make sure the hinges are correctly fitted, that the hinge blades do not protrude and therefore are not causing the door leaf to stand proud of the door frame. Reinstall as necessary. Also, are the door frame rebates sufficient to accommodate the thickness of the door leaf and not causing the door leaf to stand proud of the door frame? Remove and reinstall the planted rebate stops as necessary.